Micromachining

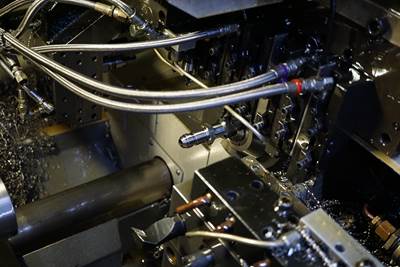

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

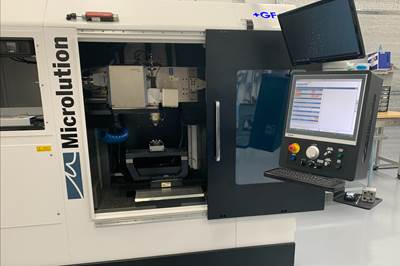

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Watch3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

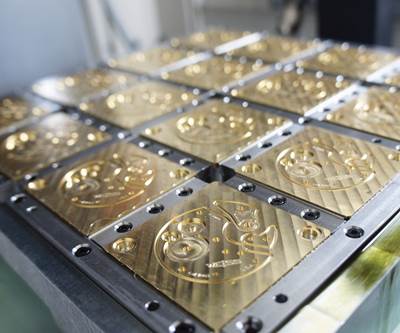

WatchWatchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreFive-Axis and Clever Controls Support Medical Manufacturing

Kern’s Micro Vario and Heidenhain’s TNC 640 control give M5 the precision and accuracy it needs to successfully micromachine medical parts.

Read MoreMicro 3D Printing Solves Big Problem for Tiny Parts

3D printing is a well-known tool for prototyping, but only recently has the technology reached the point that it can handle the tiny features and tight tolerances of micro parts.

Read MoreTransitioning to CNC Swiss-Type Machining? Here’s How One Shop Did It.

The introduction of CNC Swiss-type machines at Deking Screw Products brought a new and highly efficient production method to the business. But it also required learning the distinct differences inherent with Swiss-type machining, and a mindset change for the company’s leaders.

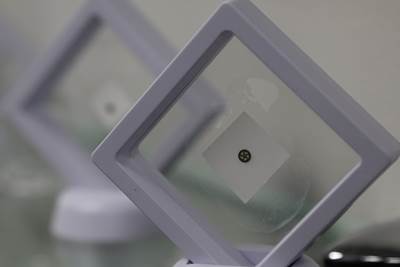

Read MoreHolding Submicron Part Tolerances

Sunlight-Tech Inc. has used GF Machining Solutions’ Microlution laser micromachining and micro-milling centers to produce parts with tolerances tighter than 1 micron.

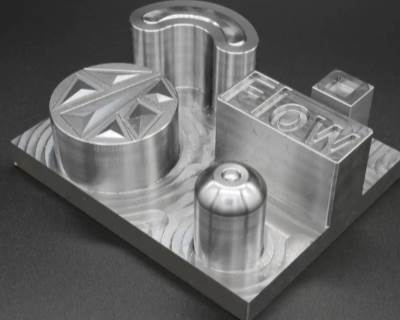

Read MoreFour New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

Read More5 Tips for Making the Switch to Micromachining

Working at the micro-level requires changing the way you approach machining parts, and these tips can help you avoid pitfalls.

Read More

.jpg;maxWidth=300;quality=90)