Micromachining

Does Small-Hole Drilling Demand a Fast Spindle?

A reader with a 10,000-rpm drill press can drill a 0.019-inch hole in stainless, as long as all the contributors to runout are controlled.

Read MoreHow Do You Get The Cutting Parameters Right For Small End Mills?

A reader recently asked about speed, feed rate and depth of cut when using small tools in steel.

Read MoreUsing Small End Mills In Steel Without Breaking

A reader wants to mill with small tools on a straightforward VMC used for full-sized work. MMS Online’s micromachining expert offers advice.

Read MoreCoolant And Center-Drilling Considerations For Machining Small Holes

Through-spindle coolant is good if you can get it, but the spot drilling might not be necessary. Try a pilot hole instead?

Read MoreWhat is the Best Process for Micro-Deburring?

Various techniques address the challenge of getting a clean machined feature at microscopic scales.

Read MoreHow Do You Machine a 30:1 Hole in Stainless Without the Drill Wandering?

An expert in micromachining says one answer is to check various aspects of the drilling process. Another answer is not to use a drill at all.

Read MoreThread Milling On A Tiny Scale

Machining internal threads in difficult materials is challenging, especially when hole diameters are small. Thread milling offers advantages for these applications that are important to consider.

WatchToo Small To Touch

Hummingbird takes on machining work that is too small for most shops to handle. In fact, Hummingbird tries not to handle it either. To accurately machine the tiniest parts, this shop relies on processes that are as hands-off as possible.

Read MoreLittle Things Mean A Lot

The design of a machining center with the precision to mill tiny features illustrates what is (and is not) required for micromachining.

Read MoreHow Scalable is Machining?

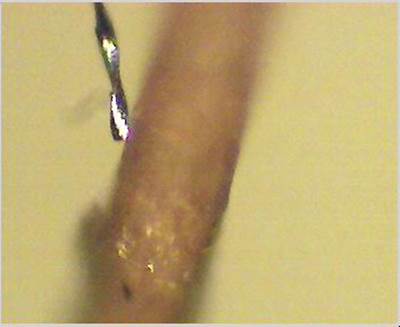

Tiny tools don’t behave like big tools do. One researcher explains why.

Read More

.jpg;maxWidth=300;quality=90)