Share

Famar (whose headquarters is near the center of the photo) celebrated its 50th anniversary in June 2023. Founded as a support shop serving only Fiat, it has since become a multinational machine tool manufacturer — though most of its work is still related to vehicles. The mountain-nestled Avigliana location houses the factory for Famar lathes, Fausto Marinello mills and Famar Automation’s in-house conveyors.

To maximize the stability of its machines, the Famar Group manufactures the bedframes for its machine tools in-house at its factory in Avigliana, Italy. It matches this level of care for the inverted spindles of its lathes, the horizontal spindles of its four- and five-axis machining centers and the multi-machine production lines that make up many of its orders. The company’s strict standards for its machines and tight control over its components has benefited its customers, as its machines offer extreme versatility as well as applicability for a wide variety of applications.

A Firm Foundation

While Famar may be an unfamiliar name to many machine shops in the US, the company has been producing lathes since 1994, with machining center production under the Fausto Marinello brand (named for the parent company’s founder, who still bicycles around the company campus) since 2012.

I visited the company’s Avigliana location in May 2023 alongside another journalist, the two of us becoming the first American reporters to view the site. During this tour, I saw some of the components Famar says make its machines unique, and observed some of the factors that inspired the Morris Group to found a new subsidiary, Select Production Technologies, to distribute these machines in the North American market.

Both Famar’s lathes and its Fausto Marinello mills have multi-spindle versions. Some can improve productivity on a single operation or perform multiple operations in a single setup, while others can perform wholly different categories of operation in the same setup.

Famar manufactures its vertical lathes using a damping “bedframe” consisting of a steel frame filled with polymer concrete. This filling contributes to both vibration damping and thermal stability, aiding the machines in achieving micron-level tolerances.

The cubic shape of the bedframe also enables simple access to the spindles on both the lathes and the mills, streamlining maintenance. The Fausto Marinello mills use the same cubic shape as the lathes to redirect vibrations, but include no filling by default — though polymer concrete filling is available as an option for the base.

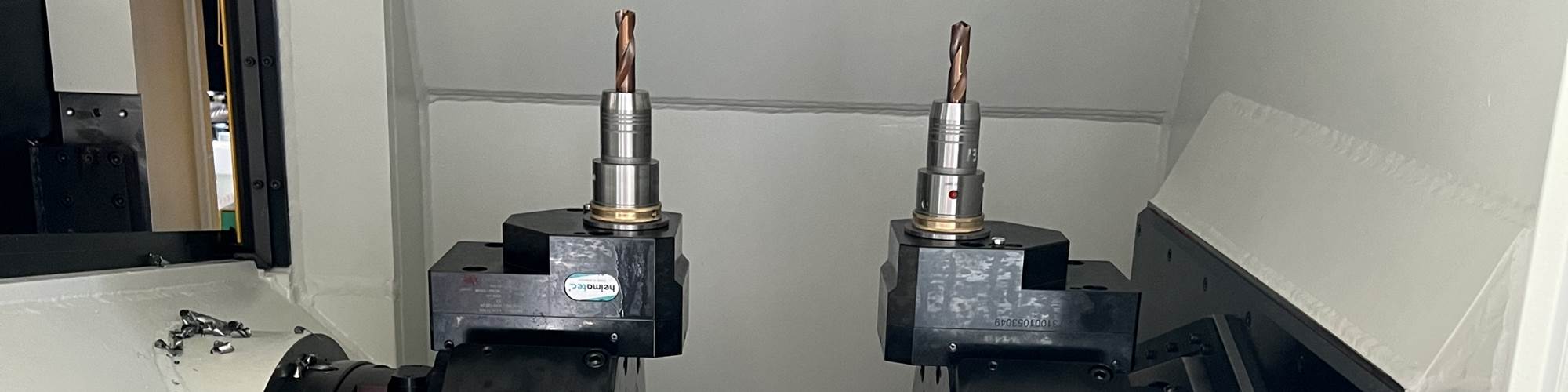

In addition to bedframes, the company assembles its spindles in-house, targeting high-end performance in horizontal five-axis milling and the uncommon niche of downward vertical turning. The inverted spindle of the lathes improves chip control and angled tooling performance, while also enabling high torque and horsepower — advantages mirrored in the horizontal mills. Famar Group has also designed these spindles to be compatible with high-pressure through-coolant.

The direct-drive turrets are attached to the bedframe, improving rigidity and eliminating the need for transmission gears. The company says both its lathes and mills can utilize their maximum torque even from 0 rpm. Standard speeds for the lathe spindles can reach up to 7,000 rpm based on size and machine model, with the milling spindles reaching up to 17,500 rpm — though users can work with the company if they require custom, even faster spindles.

Federico Marinello, managing director and chief executive officer of Fausto Marinello, says that making spindles accessible from the back simplifies maintenance. The machines also maintain a compact footprint on the floor, with extended tool magazines to the side (and above) on the mills.

Fausto Marinello mills take two main forms: single-spindle FM 1 machines, and two-spindle FM 2 machines. The FM 1 is available with single or double five-axis rotary tables, while the FM 2 comes standard as a four-axis machine with optional single or double rotary tables for five-axis work.

Tool changes all take place outside of the machine area, with chip-to-chip times between 2.5 and 3.5 seconds. Pallet changers are available on both machine types, and triple guideways prevent ram bending. Chip management is relatively simple on both types of mill, as chips fall directly onto the machine conveyor. Additionally, the rotary tables have internal rotary joints that simplify maintenance.

As the longer-running subsection of Famar Group, Famar’s selection of turning machines includes a wider range of standard options: the Ergo, Pronto, Maxer, Sub and Tandem. The Ergo is Famar’s mainline lathe, with the Pronto as a less-expensive, less-customizable version and the Maxer as a variant with a Y-axis milling spindle.

Famar also offers left- and right-hand versions of the Ergo. The Sub is a smaller machine that boasts a three-second loading time, though its Sub Nano 3G variant can use a “pendulum mode” to switch between its two spindles and turrets. This enables it to actively machine with one turret while changing out the workpiece for the other turret for what the company says is a zero-second loading time. A BiSub variant takes a different approach to increasing productivity, with two machining areas, each supplied with its own spindle.

Famar’s Tandem machine extends this idea with two machining areas on one machine tool, each fed by its own independent pallet conveyor and damped by a separate bedframe bolted together near the centrally-located control, enabling simultaneous machining of two parts or complete machining in two stages.

Oodles of Options

In addition to machine lines, versatility in Famar Group’s machines manifests as customizations that add additional functionality. The same base machine can be optimized for different part families with the right customizations. Similarly, full production lines can include machines with different customizations to work on multiple part families.

By equipping a lathe with the right customizations from Famar, users can perform not just turning, but skiving, grinding and milling, converting their lathe into a multitasking machine.

For Famar’s lathes, this manifests as nine different “options,” in addition to five “special applications” and an optional probe. The options alone can add elongated bedframes for additional work units, a gear hobbing or skiving spindle, grinding capabilities, extra turrets for multiple drilling or tapping operations, machining outside the axis of rotation, non-cylindrical machining and horizontal milling. Not every option is compatible with every type of lathe, but some options can be combined for especially versatile machines.

Famar also produces an in-house probing option, which can swing out to take measurements and retract when need be, enhancing its usability for long parts and helping it to avoid chips and coolant. Users can also choose between the default Siemens Sinumerik One controls and an alternative option from FANUC.

Design for Automation

This flexibility persists through Famar’s automation options. The company maintains an automation division that produces six types of conveyors and feeders in-house, but it also integrates customer-owned robots and support machines into automated cells.

Famar’s lathes also use the in-house Infinity system, which replaces tools during loading and unloading to reduce changeover time. Famar also offers its own software for tool management to further simplify the process.

Famar develops its own automation systems in-house, a task which has given its engineers plenty of integration experience. The company can also design automation cells to use customers’ existing robots.

Combining the different machines and options into a single automated line is a tall order, and one that Famar tackles by testing the entire cell twice: once in the Famar Group factory, and again on the customer’s shop floor. During my visit, two notable cells undergoing testing on the factory floor included one with multiple lathes (each with additional options), two robots, a 3D camera for parts scanning, a laser marking unit, and an in-house basket feeder unit — which could swap which side was active depending on which side was full at the time.

The other cell embodied the idea of customizing a single base type of lathe to tackle multiple part families. In addition to its customized lathes, this cell used rollers to send parts to turnover stations for inspection at regular intervals, with a 3D camera confirming the part’s orientation after it returns to the production line.

Customer-Centric Support

Famar has tried to keep maintenance as flexible as its machines. Remote troubleshooting is the standard, with an option to give Famar support engineers remote access to machine controls to solve any issues. For shops with security requirements preventing remote access, the OEM is looking more into self-serve troubleshooting offerings.

Shop maintenance personnel can use their phones to take pictures of the machine and get a step-by-step visual guide to repairs. They can also use hyperlinks to directly enter information into Famar’s support portal to get advice from the OEM without connecting machines to the internet.

Famar sales director Beatrice Marinello says that most of the company’s work consists of full automation cells, with multiple Famar machines integrated with support machines and robots. Ordering single machines, though less common, enables much swifter delivery.

This web-based support is especially valuable as Famar only maintains support offices in Germany and China, with the headquarters and factory in Avigliana tripling as a central hub for Italian support and repair parts. Beyond these areas, swiftly fulfilling repair part requests is the role of distributors, a role now filled in the US by Select Production Technologies. Famar’s machines are the first to be distributed by this new branch of the Morris Group — but the machines from this one OEM will serve many applications.

Related Content

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreSwiss-Type, Live Tooling Lathes Help Turn Company Around

New leadership’s investment in Swiss-type and live tooling lathes has enabled Rathburn Tool & Manufacturing to expand into new markets, reversing the company’s sluggish growth.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreInside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreRead Next

Automation Cell Outperforms CNC Machines Fourfold

An automated turnkey machining cell simplified one Utahan manufacturer’s part handling and halved its cycle times.

Read MoreBuying a Lathe: Slant-Beds and Multitasking Configurations

What are some variations on the basic lathe configuration? This can be helpful to review when considering the purchase of a new turning machine.

Read MoreMultitasking Machining Equipment: Now the New Normal

Equipment that can turn, mill and more is quickly becoming the standard in metalworking technology. These machines can produce increasingly complex parts in a single setup yet are easier operate than ever before.

Read More