Machining Centers

Pallet System Software Boosts Cell Flexibility

The software running this shop’s newest FMS from Fastems adds a layer of automation that enhances the inherent flexibility, productivity and effectiveness of lights-out operation. Dynamic job scheduling is the key.

Read MoreHorizontal Boring Machine Handles Large Workpieces with Thermal Stability

Soraluce’s KB-150-WR T-type horizontal boring machine provides high efficiency and durability for multi-face machining of large workpieces.

Read MoreFive-Axis Mill Provides Continuous Operation, Increased Spindle Uptime

The Mikron HEM 500U high-efficiency milling machine from GF Machining Solutions includes a 10-position pallet changer and provides high-performance five-axis capabilities for efficient, accurate and reliable production.

Read MorePeople are Part of the Process for Machining Inconel

A Tacoma shop describes its winning strategy for efficient machining of Inconel. That strategy includes careful choices of cutting tools and cutting parameters. It also includes a healthy breakfast.

Read MoreCompact VMC Designed for Moldmakers

Designed for the moldmaking, tool and die, and medical industries, the compact VM-2 vertical machining center from Haas Automation provides accuracy, rigidity and thermal stability required for high-precision work.

Read MoreMicromachining Center for Die/Mold Applications

Available from Methods Machine Tools, the Yasda YMC 430 Ver. II micromachining center is designed for precise manufacturing and high-quality surface finishes required on small, complex features in components, dies and molds for applications in the medical and semiconductor industries.

Read MoreMicromachining Center Promotes Component Temperature Control

Makino’s iQ300 precision micromachining center offers improved component temperature control and 0.005-micron scale feedback for sub-micron accuracy.

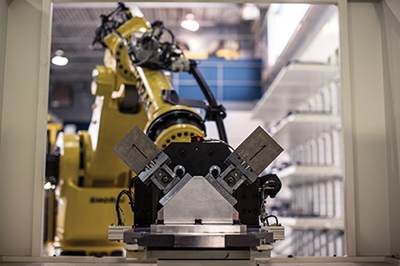

Read MoreAutomated Five-Axis Cell Streamlines Production

Abipa Canada made its move into automation leveraging a fixture plate distribution system and an HMC, minimizing setup time and lowering part production costs.

Read MoreTwin-Spindle HMC Precisely Machines Small, Medium Workpieces

The BA 322 from SW North America is a compact, twin-spindle HMC designed for four- or five-axis machining of small- to medium-size steel, cast iron and light metal workpieces such as brake calipers, hydraulic valves and turbocharger components, including compressor wheels.

Read MoreVMC Accommodates Large, Heavy Workpieces

The base column of Okuma’s Millac 852V II vertical machining center features ribbing to counter chatter and twisting during heavy-duty cutting.

Read More

.jpg;maxWidth=300;quality=90)