Machining Centers

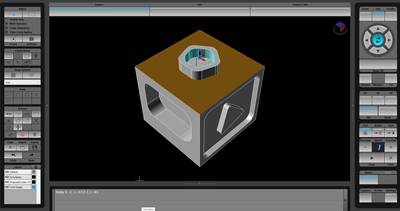

Comau, Exechon Collaborate on Machining Center Design

The machining center will be designed particularly for manufacturing lightweight framing and structural components for the automotive and aerospace sectors.

Read MoreTaking an Automated Aerospace Approach

A flexible manufacturing system helps an Indiana job shop run a high mix of aerospace work for long stretches of time and function more like a contract shop.

Read MoreMazak’s FJV-35/80 VMC Offers High Precision for Large Workpieces

Mazak’s FJV-35/80 double-column VMC is designed to provide high precision over extended periods of operation with intelligent CNC functions and rigid construction.

Read MoreThe Manifold Benefits of Standardization

By locking in on manifolds, investing in one HMC model and developing custom software used on iPads in every department, this shop has set itself up for continuous improvement and its new employees up for success.

Read MoreShop Reins in Lead Times with Compact HMCs

Alicat Science experienced a surge in business that drove lead times to 28 days. KMH300A horizontal machining centers reduced lead times to five days and gave the shop the capacity for subsequent business growth.

Read MoreFive-Axis Conversational Programming from a Solid Model

This CNC feature imports a 3D solid model from which operators can perform conversational-type programming even for five-sided machining applications.

Read MoreDeveloping a Five-Axis Solution for Machining Superalloy Aerospace Parts

Growing involvement in producing multi-blade aerospace parts made of superalloys presented Pietro Rosa with some machining challenges. Starrag’s LX 021 five-axis VMC helped the shop achieve tight tolerances and integrated production.

Read MoreBoehringer VDF 221/226 CET Meets Evolving Demands in Crankshaft Machining

Responding to the need for higher productivity and efficiency in crankshaft machining, Boehringer, a member of FFG, introduces its VDF 221/226 CET.

Read MoreWhy Was CNC Machining on Display at the Biggest Show for Additive Manufacturing?

Machining is a complement to AM as a means of finishing metal 3D printed parts. The increasing adoption of AM for production means more need for postprocessing, particularly machining.

Read MoreKitamura's Mycenter-HX300iG 400 Combines Large Work Area in Small Footprint

Kitamura Machinery’s Mycenter-HX300iG/400 expands the company’s small-footprint HMC offering, providing heavy-duty cutting, accuracy and reliability.

Read More