Machining Centers

Heller Announces New Distribution Partnership

Dynamic Machine is now Heller Machine Tools’ distributor for the regions of Michigan, Western Pennsylvania and Canada.

Read MoreMazak to Open New Technical Center in Edmonton, Canada

The new Technical Center will support customers in Manitoba, Saskatchewan and British Columbia specializing in industries including oil and gas, agriculture, maritime, aerospace, mining, and forestry.

Read MoreGrowing a Job Shop into a Full-Service Manufacturer

By maximizing employee satisfaction, adding fabrication and other services, and always keeping open machine capacity, Square Deal has grown from a seven-person job shop to a full-service manufacturer that employs hundreds.

Read MoreA More Affordable Approach to 5-Axis Large Part Machining

Shops that machine large aluminum parts don’t have to pay millions of dollars for a machining center just to get the work envelope they need. There is a more affordable alternative, and it’s manufactured in the USA.

Watch5 Hard Lessons from a 28-Year-Old Startup Machine Shop Owner

Good fortune and years of long working hours have both figured into the success of this young shop, which became its founder’s sole employment starting last year. The shop owner shares his story.

Read MoreCincinnati Inc., Multiax America Form Partnership

“Because an overwhelming majority of BAAM-printed parts require secondary machining, we’ve had a goal to partner with a leading CNC machine manufacturer for some time,” says Alex Riestenberg of Cincinnati Inc.

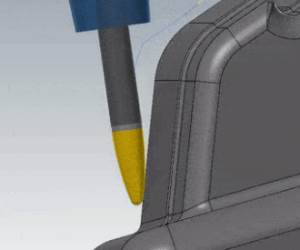

Read MoreHow to Slash 5-Axis Finishing Time

Finally there is an alternative to ballnose endmills for finishing 3D parts. The combination of finishing tools shaped to provide more cutting surface and a CAM system with the ability to apply them on a five-axis machining center can dramatically reduce finishing cycle times while delivering better surface finishes.

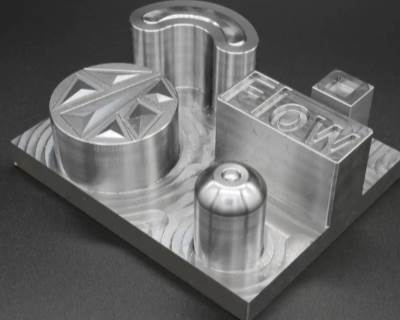

Read MoreFour New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

Read MorePortal Milling Machine Provides Years of Smooth Operation

Neuman & Esser uses their eight-year-old Droop+Rein from Starrag as a “workhorse” for complete machining.

Read MoreStarrag's STC-MTV Five-Axis Mill-Turns Specialize in Hard Metal Machining

IMTS Spark: Starrag’s STC-MTV five-axis multitasking HMCs are designed for hard metal machining in such sectors as aerospace and oil and gas.

Read More