Machining Centers

SW’s BA 322i Operates as an Independent Machining Cell

EMO 2019: Schwäbische Werkzeugmaschinen’s BA 322i is designed as an independent cell.

Read MoreBurkhardt+Weber’s MCX 900 Accommodates Large Parts and Tooling

EMO 2019: Burkhardt+Weber’s MCX 900 horizontal machining center is designed for accuracy, accommodating part sizes fitting within a 1,500 mm (59") swing and as tall as 1,750 mm (69").

Read MoreMilltronics' VM250IL-5x Includes 40-Station ATC

EMO 2019: Milltronics’ VM250IL-5x five-axis vertical machining center features a trunnion table 255 mm in diameter and XYZ axis travels measuring 550 × 508 × 520 mm.

Read MoreWaldrich Coburg's Gemini Features Wear-Free Hydrostatic Guides for Accuracy

EMO 2019: Waldrich Coburg’s Gemini is a high-rail gantry system designed to be used in the die and mold industries.

Read More4 Examples of American Machining Evolution

A tour of this 160-year-old machine tool manufacturing plant in Fond Du Lac, Wisconsin, highlighted the progress of both the company and machining technology in general since the dawn of “Industry 1.0.”

Read MoreMazak's VTC-300 FSW Hybrid Applies Friction Stir Welding

Westec 2019: Mazak’s VTC-300 FSW Hybrid multitasking vertical machining center features friction stir welding (FSW) capabilities.

Read MoreHow Metal Burnishing Can Significantly Improve Product Life

Lambda Technologies’ low-plasticity burnishing process strengthens machined metal parts to extend product lifespans without compromising part geometry.

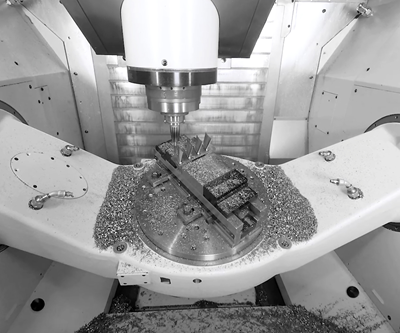

Read MoreGrob’s G350a and G550a Include Features for Stable Machining

EMO 2019: Grob’s new Access series includes two flexible all-rounder universal machining centers, the G350a and G550a, which are designed for reliability and high productivity.

Read MoreRoboDrill EcoPlus Offers Increased Machining Speed

FANUC RoboDrill EcoPlus offers a 21-tool capacity and increased speed through an optional 24,000 rpm spindle.

Read MoreChiron's FZ 16 S Five-Axis Machining Center Meets Aerospace Requirements

The Chiron Group’s FZ 16 S five-axis machining center with tilting rotary table is specialized for aviation sector requirements.

Read More