Machines

Where New Machines And Methods Overshadow The Old

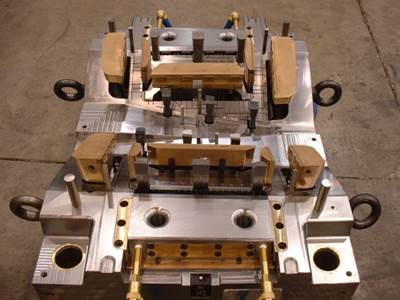

Eclipse Mold makes a good case for high-end machining centers as the basis for effectively machining to zero.

Read MoreCutting To The Model

This mold shop's cutting tool strategies help it eliminate hand spotting altogether by machining complex molds directly to the CAD model.

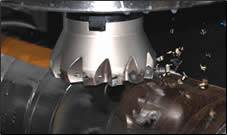

Read MoreRealizing Large-Scale Savings On Large-Scale Parts

Converting big square bars to largely round tie bars used to require 24 hours per piece at Oak Products. The Sturgis, Michigan, company can now complete the same job in 8 hours. How did the company slash its machining times and realize substantial cost savings? Oak attributes the turnaround to process re-engineering involving aggressive mill-turning and tooling geared to stand up to the challenge.

Read MoreSeeing More For CNC Multi-Spindles

Motor technology, machine design and software possibilities all improve the economies of these sophisticated high-volume machines.

Read MoreGrinding’s Role In A Thermal Spray Shop

Cylindrical grinding is the final step in bringing worn components back to size after applying a build-up coat of molten metal.

Read More

.jpg;maxWidth=970;quality=90)