Machines

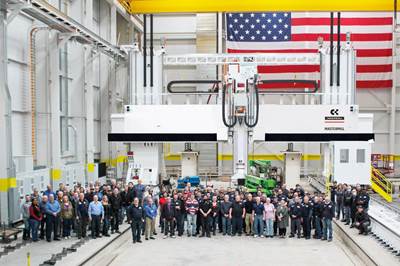

Machining Facilities Launch Drives American Manufacturing

New five-axis machining center accompanies the opening of 40,000 foot expansion to Ingersoll Machine Tools facility.

Read MoreDynamic International's VMC Series Provides Cutting Force Absorption

The SV Series from Dynamic International is a set of vertical machining centers focused on stability while cutting.

Read MoreLarge Surface Grinders Are 20 Percent More Efficient

New FSG-2048ADIV and FSG-2064ADIV machines from Chevalier Machinery offer several design features to mold builders to shorten processing and non-processing preparation while delivering high-precision workpieces.

Read MoreExpand Machinery Swiss-Type Machine Offers 33 Tool Positions

Expand Machinery’s Genturn-52CS Y2 features a subspindle as well as dual C and Y axes to enable multiple operations in a single handling.

Read MoreTrunnion Style Machining Center Built for Precise Production

IMTS22: Hwacheon's D2-5AX is designed for heavy duty, precise five-axis machining and features an automation option with automatic workpiece changer.

Read MoreWhen Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

Read MoreGrinder Works on Two Surfaces Simultaneously

IMTS22: Double disc grinders from Supertec Machinery possess a multitude of benefits that have applications across a variety of different industries, including automotive, aerospace, marine, and many more.

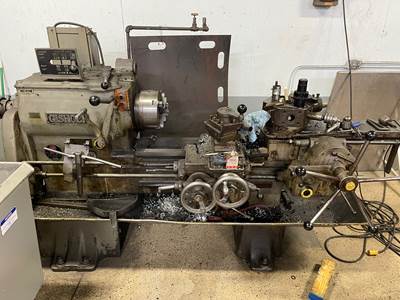

Read MoreInside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read More

.jpg;maxWidth=970;quality=90)