A New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Share

In milling, cutting forces are exerted in three planes to deform and shear away material in the form of a chip. Tangential cutting forces overcome the resistance to rotation and account for 70 percent of the total force. Feed forces account for 20 percent of the total force. Radial forces tend to push away the tool and account for 10 percent of the cutting forces.

The tool's rake controls the degree of cutting forces and power consumption, the strength of the cutting edge, and the direction of chip flow. As a rake angle becomes more negative, cutting forces increase and edge strength improves. A dependent rake is based on the lead angle of the tool and is common for external turning tools. An independent rake is applied regardless of the design of other tool angles and is typical for most rotating cutting tools and boring tools.

The tool's lead is the approach angle of the cutting edge as it enters the workpiece. The lead controls the direction of the radial and axial cutting forces, provides effective chip thinning, and protects the weakest part of the cutting edge.

The tool's clearance is an angled relief behind the cutting edge that eliminates interference between the cutting tool and the workpiece. Clearance is required to reduce rubbing or burnishing and allow for adequate chip flow. Different workpiece materials require different clearance angles, especially if the workpiece is expected to cause spring back.

A milling cutter's performance is limited by its maximum chip load. Since commonly used speed and feed calculators show only feed per tooth, expressed as fz, the terms "chip load" and "fz" tend to be used interchangeably. This common misconception can lead to significant error.

Always remember that chip load refers to chip thickness, not fz. Rather, fz is the increment of feed that takes place by one insert in one revolution of the cutter. Chip thickness is the amount taken by each insert as it advances through the arc of the cut. The metal removed by a single pass of one insert looks like a very thin crescent. Chip thickness is the thickness of the crescent anywhere along its arc, which makes its thickness vary from zero to a maximum usually equal to the fz. Chip thickness increases until it equals the fz at the centerline of the cutter. Feed per tooth and chip thickness are equal only at the point where the crescent crosses the direction of feed, which is usually at the cutter centerline. In other words, fz is a constant for a given operation, and the chip thickness is a variable that changes cyclically.

Milling cutters can consume significant amounts of horsepower. Very often it is the lack of horsepower that is the limiting factor when deciding on a particular operation. On applications where large-diameter cutters or heavy stock removal is necessary, it is advantageous to first calculate the necessary horsepower requirements.

NOTE: Spindle efficiency “E” varies from 75% to 90% (E = 0.75 to 0.90).

A suitable formula for calculating horsepower (HPC) at the cutter is:

HPC = MRR/K

|

Example: Width of cut (ae) 1.64" Depth of cut (Ap1) .200" Feed (vf) 19.5 ipm 4140, 220 HB “K” factor 1.56 |

MRR = Ap1 x ae x vf

MRR = .200 x 1.64 x 19.5 = 6.4 in3/min

For horsepower at the motor (HPm), use formula:

HPm = HPC/E

In determining horsepower consumption, “K” factors must be used. The “K” factor is a power constant that represents the number of cubic inches of metal per minute that can be removed by one horsepower. NOTE: “K” factors vary depending on the hardness of the material.

Workpiece Material K factors

Workpiece material Hardness (HB) K factor

Steels, plain-carbon alloy steels, 5-200 1.64

tool steels, wrought irons, cast irons 201-253 1.56

254-286 1.28

287-327 1.10

328-371 0.88

372-481 0.69

482-560 0.59

561-615 0.54

Precipitation-hardening stainless steels 150-450 1.27-.42

Cast irons (gray, ductile, malleable) 150-175 2.27

10-190 2.00

176-200 1.89

201-250 1.52

251-300 1.27

301-320 1.19

Stainless steels, wrought irons, cast irons 135-275 1.54-.76

(ferritic, austenitic, martensitic) 286-421 .74-.50

Titanium 250-375 1.33-.87

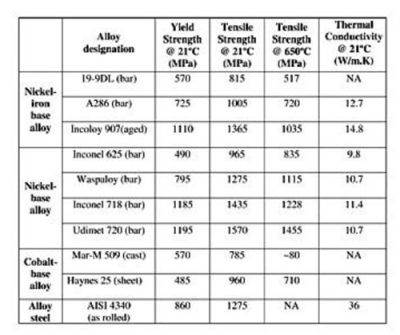

High-temp alloys, nickel- and cobalt-based 200-360 .83-.48

Iron-based 180-320 .91-.53

Nickel alloys 80-360 .91-.53

Aluminum alloys 30-150 (500 kg) 6.25-3.33

Magnesium alloys 40-90 (500 kg) 10.0-6.67

Copper 150 3.33

Copper alloys 100-150 3.33

151-243 2.00

In addition to power calculations, geometry aspects of peripheral milling cutters also are important, namely helix and rake/clearance angles. Most peripheral milling cutters are made with helical teeth. Helical teeth enter the workpiece at a single point with impact progressively increasing across the width of the cut. If the width of the workpiece is a whole multiple of the axial pitch of the cutter, a helical cutter can be designed to cut with practically uniform cutting force, explaining their wide preference.

With straight teeth, while the impact at entry occurs over the entire width of the cut, the chip load is released at exit and the cutting force drops to zero, resulting in violent fluctuations in cutting force.

Rake angles can be positive or negative. A positive rake angle has a small cutting zone with a high shearing angle and generates tensile stress due to its cutting action. A negative rake angle, by comparison, has a large contact zone and low shearing angle and generates compressive stress as it cuts. In general, positive rake angles are recommended for aluminum and milder steels with negative rake angles being a better choice for medium and harder steels.

Round inserts with a positive geometry are usually called upon when a strong insert edge is needed. With more cutting edges and high axial forces, round cutters are usually recommended for milling with high-impact loads and high-strength materials.

Cutter diameter and the pitch of the teeth also are vital considerations. In general, one should use the smallest cutter that can transmit the power required and provide economic tool life, given the following (all things being equal, that is—constant cutting speed, feed per tooth, and pitch of teeth):

1. The larger the cutter diameter, the smaller the mean chip thickness, therefore force on the individual tooth is smaller.

2. Larger-diameter cutters are capable of transmitting greater power as they are carried on a larger-diameter arbor.

3. Larger-diameter cutters will give greater tool life, given the greater number of teeth, but larger-diameter cutters also exhibit increased cycle time due to increase in the approach time of the cutter.

Factors for selecting pitch of the teeth are:

1. At constant feed velocity and for the same diameter of cutter, the fewer number of teeth (coarse pitch) means higher cutting force per tooth.

2. Long-chipping material needs more chip space than short-chipping material, hence long-chipping material needs a coarser pitch than short-chipping material.

3. The number of teeth should be such as to allow sufficient room for chipmaking at the highest feed rates at which the cutter will be operated.

4. Light alloys allow higher feed rates, so applicable cutters should have fewer teeth to provide more chip room. Consequently, higher-strength materials (chrom-moly or chrom-tungsten steels) have higher specific cutting pressure, so a medium- or fine-pitch cutter should be used to keep forces within limits for each cutting tooth.

Face milling is used for creating a flat surface (face) on the workpiece surface. The cutting plane is usually perpendicular to the axis of rotation and the cutters most often feature a single row of inserts. Surface finish requirements are an important input to determine the best tool type. Typically, face milling is performed by tools offering a lead angle for long tool life and reduced chance of breakout when exiting the workpiece.

Face milling may include a simultaneous shoulder milling operation. Unlike face milling, shoulder milling takes place with the cutting plane parallel to the axis of rotation, creating a flat or contoured surface on the workpiece periphery. Typical shoulder-milling cutters usually have one or more rows of inserts.

Slot milling creates a slot or channel in the workpiece. Cutting planes are both parallel and perpendicular to the axis of rotation. Slotting may also include simultaneous side and bottom cutting.

Tool Cutting Edge Angle

Different angles at the cutting edge generate different-thickness chips. For example, a 45-degree cutter has equal radial and axial forces, making it less demanding on spindle bearings and enabling higher feed rates. This is usually a good choice for face milling as it provides a smooth entrance and exit to the cut while offering high surface finish quality.

The greater the lead angle, the lower the chip-thinning effect. A 90-degree cutter, therefore, will have high insert loads because chip thickness is at maximum for a given feed.

In General

Choosing how to mill a given part involves many considerations. What kind of machine tool is best? How much horsepower is available and how rigid is the machine? How is the part fixtured? Are clamps in the way? Can the tool reach the part, and is the nose diameter of the tool appropriate? Can chips fall away from the tool?

Whether face milling, periphery milling, slot milling, or specialty milling in general there are three main considerations – the metal removal rate, the surface finish, and the tool life (number of parts possible per tool). While all these factors wield considerable influence on what tool is right for a given situation, one of these factors will predominate and the others, while important, will be subordinate. Carefully analyzing and selecting tool material, construction, and geometry can significantly minimize overall costs and optimize your production process.

Part 4 of A New Milling 101 focuses on material grades and coatings and how they affect achieving maximum milling performance.

Editor’s note: You can read the next part by clicking here.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreRead Next

A New Milling 101: Selecting Tool Materials and Coatings

Part 4. The emergence of new workpiece materials is driving the development of new cutting tool materials and tool coatings. These, in turn, are driving the development of new milling processes and techniques.

Read MoreA New Milling 101: What Customers Demand

Part 5. For W Machine Works in San Fernando, a custom variation of the WIDIA-Hanita VariMILL II solid end mill proved especially effective in roughing and semi-finishing applications in stainless steels, high-temp alloys, nickel- and carbon-based alloys, and titanium.

Read MoreA New Milling 101: Cutter Design and Application Considerations

Part 2: Cutting tool geometry governs almost all design and application considerations related to various milling choices.

Read More