Machining Facilities Launch Drives American Manufacturing

New five-axis machining center accompanies the opening of 40,000 foot expansion to Ingersoll Machine Tools facility.

Share

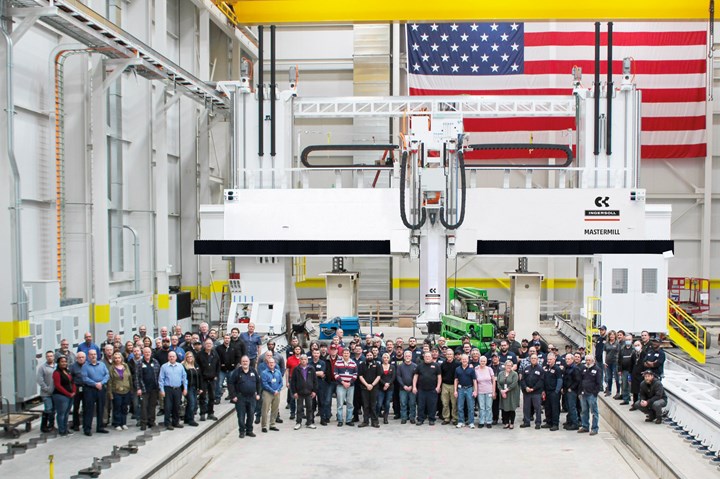

Ingersoll Machine Tools launches its largest and most advanced machining center, the five-axis MasterMill, as part of a new 40,000 square foot expansion for manufacturing, assembly and extended testing facility in Rockford, Illinois.

The MasterMill and facility are initially undertaking complex machining for the US Navy and manufacturing large components for the Giant Magellan Telescope. The company says the MasterMill and facility also spearhead the growth of American manufacturing, private-public partnerships, job creation, skills advancement and development of young manufacturing leaders.

The grand opening event includes advanced manufacturing demonstrations using MasterPrint Robotic, Ingersoll’s robotic version of its XL thermoplastic 3D printer. There are also demonstrations with MasterPrint Metal, the world’s largest metal 3D-printer, and the Mongoose Hybrid, Ingersoll’s multi-process composite manufacturing platform.

Mongoose is used for space, aerospace and defense projects. It plans to soon produce the main structures for the world’s largest optical telescope, which will be assembled in the new building.

Ingersoll Machine Tools provides many other advanced manufacturing processes while also supplying additive and subtractive machine tools for the aerospace, defense, energy and all heavy industrial sectors worldwide. Together with Innse-Berardi, Ingersoll constitutes the Camozzi Machine Tools division of the Camozzi Group.

Related Content

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.jpg;maxWidth=300;quality=90)