Machines

“Smart” Generator Technology Makes EDM Operation Intuitive

GF Machining Solutions offers four generator features that enable users to input desired burning results into the CNC, and let the system do the rest.

Read MoreShop Transitions to Aerospace Work with CNC Grinder

J&E Precision Tool met increased demand for complex, high-precision parts with the Studer S33 grinder from United Grinding, leading to improved workflow, part quality, machine utilization and quoting.

Read MoreEDM Cell Cuts Lead Time in Half, Improves Quality

Sodick's AG60L sinker EDM and an Erowa Robot Compact helped Ford Tool and Machining LLC cut lead time in half when it needed to reduce downtime and increase repeatability.

Read MoreIncrease Machining Efficiency through Machine Monitoring

A manufacturer that is distinctive for its attention to in-cycle machining productivity describes its efforts to obtain efficiency improvements outside of the machining cycle. The shop’s primary tool is a simple, daily, graphical recap that illustrates when each machine tool was and was not making parts.

Read MoreSmaller Universal Cylindrical Grinder Offers Two-Spindle Turret

The S121 from Studer, a brand of United Grinding, is a universal internal/external cylindrical grinding machine for medium-sized workpieces, particularly chuck components and drive elements, in individual and small-batch production.

Read MoreGrinding Oil Filtration Suits High-Production Machines

Vomat’s FA-series fine-filtration systems provide grinding oil quality to purity Class 7 NAS with a particle size of 3 to 5 microns to ensure that coolant remains in good quality for economical production grinding.

Read MoreSpindle Unit Enables Grinding with a Robot Arm

Suhner offers a series of spindle units designed to be used with robot arms for drilling, milling, deburring, grinding or brushing operations, including the BEX 15 WW-ER 25 for grinding applications in mild steel.

Read MoreGear Grinder Eliminates Need for Cutting Oils

Samputensili’s SG 160 Sky Grind, available from Star SU, is said to eliminate the need for cutting oils during the grinding of gears after heat treatment.

Read MoreFive-Axis Blends Require Minding Ballnose Tolerances

Proper symmetry, expressed via the end mill’s diameter and radius tolerance, is critical to ensure smooth surface finishes during five-axis contouring operations.

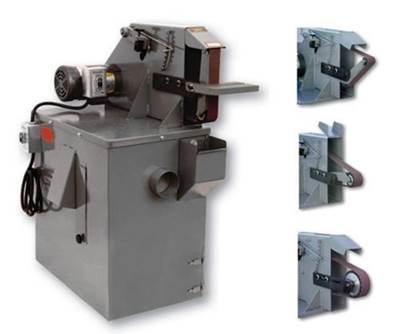

Read MoreBelt Grinder Shapes, Contours, Roughs Flat, Angled Workpieces

The multi-purpose S272V belt grinder from Kalamazoo Industries features 3" and 1½" quick-change contact wheels, plus a platen that rotates 360 degrees.

Read More

.jpg;maxWidth=300;quality=90)