High-Speed Machining

The Hard Milling Imperative

Hard milling allows mold components to be machined in the hardened state, thus skipping several expensive and time-consuming processes such as electrical discharge machining and hand polishing.

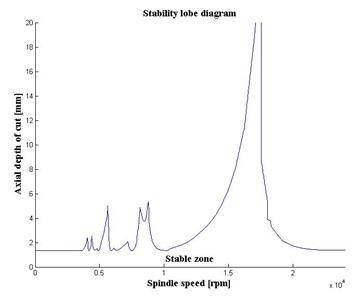

Read MoreChatter Control For The Rest Of Us

This shop finds stable milling speeds quickly using a systematic pattern of test cuts.

Read MoreTen Questions About Chatter

If you want to use a high speed milling spindle to machine aggressively, then information about chatter should be more than just background noise. Here are some basics.

Read MoreSelf-Improving CNC

This control feature lets a CNC running the same part several times get better and faster with each attempt.

Read MoreUnderstanding Jerk Control

What does "jerk" refer to, and where does it fit into machine performance?

Read MoreThe Mold Consultant

This mold maker saves customers time and money by getting involved early in the design of molded parts.

Read MoreWho's Afraid To Cut To Zero?

Most U.S. mold shops still leave extra stock on the cores and cavities of the molds they machine. This practice is unnecessary and wasteful, say proponents of advanced machining technology.

Read MoreOptimize Cutting Efficiency, Optimize Throughput

A machining process based on maximizing cutting efficiency, rather than speeds and feeds, offers aerospace component manufacturers an option to high speed machining when high material removal rates are required. The best strategy may be to apply both machining concepts.

Read MoreMold Machining And Beyond

Adopting high speed machining entailed some surprises. One of the surprises was an unforeseen opportunity for new work.

Read MoreWhen Little Things Mean A Lot

Measurement technology plays a role on machining centers used at high speeds.

Read More

.png;maxWidth=300;quality=90)