EDM

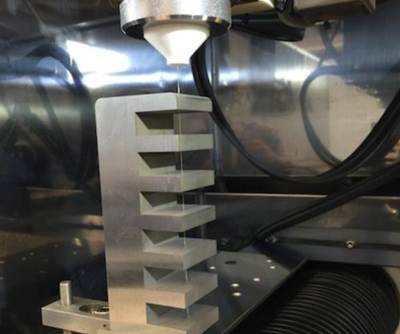

Graphite Mill Armed with Oil Cover to Capture Dust

EDM Network will exhibit its HM43GT high-speed graphite milling machine, which features an “oil shroud” option that completely surrounds the 30,000-rpm spindle with EDM-compatible oil to capture all of the graphite dust created by the end mills.

Read MoreSinker EDM Accommodates Large Workpieces

Makino’s EDNC21 sinker EDM provides dual heads to improve productivity and lower the tool build time for large molds.

Read MoreSinker EDM’s Power Supply Enables Exotic Material Machining

MC Machinery Systems offers its EA12PS sinker EDM, designed with a fixed-table traveling column and intended for medium-sized sinker machining applications.

Read MoreEDM’s HMI Makes Job Management Flexible

GF Machining Solutions offers the AgiesCharmilles Cut E 350, incorporating a range of technologies designed to increase flexibility and accelerate time to market for medical manufacturing.

Read MoreWaterproof Edge Finder Aligns Spindle to Center

Bilz Tool Co. introduces Diebold’s 3Dpro waterproof 3D edge finder for use with EDMs.

Read MoreExpanded Sinker EDM Series Accommodates Large Workpieces

Makino has expanded its EDNC series of sinker EDM machines with the EDNC10, EDNC15 and EDNC20 models.

Read MoreEDM’s Dry Annealing Process Stiffens Wire

Seibu’s M35B high-precision wire EDM provides X-, Y- and Z-axis travels measuring 13.8" × 9.8" × 9.0" and is ideal for the machining of small to medium size parts.

Read More“Smart” Generator Technology Makes EDM Operation Intuitive

GF Machining Solutions offers four generator features that enable users to input desired burning results into the CNC, and let the system do the rest.

Read MoreEDM Cell Cuts Lead Time in Half, Improves Quality

Sodick's AG60L sinker EDM and an Erowa Robot Compact helped Ford Tool and Machining LLC cut lead time in half when it needed to reduce downtime and increase repeatability.

Read MoreSuite of Productivity Technologies Applied to Complete EDM Line

Makino's full line of wire EDM, sinker EDM and EDM hole-drilling machines are now equipped with the company's s suite of Hyper Technologies, previously introduced for U-series wire EDMs,

Read More

.jpg;maxWidth=300;quality=90)