EDM

Submerged Wire EDM Expands Capacity

The AU-1440iA Z800 submerged wire EDM From Absolute Machine Tools is designed to quickly and accurately process large as well as smaller parts.

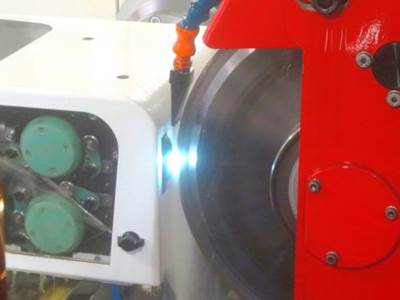

Read MoreElectrical Discharge Device Dresses Metal-Bonded Grinding Wheels

Available from United Grinding, the Studer WireDress electrical discharge wheel dresser uses the wire erosion principle to dress metal-bonded grinding wheels on the grinding machine without the need to remove the wheel for external dressing.

Read MoreWire EDM’s Z-Axis Capacity Accommodates Die/Mold Applications

Sodick’s VZ500LH was designed to meet the need for wire EDMs with large height capacity for die/mold, aerospace and energy applications producing parts such as turbine hubs, aerofoil vanes, instrument panels and mold cores.

Read MoreEDM Wire Increases Machining Speeds

The SST Consumables Group offers EDM wire optimized for use on Makino EDMs equipped with HyperCut technology, including the U3 and U6.

Read MoreUnattended Sinker EDM Burns, Shaped Diffuser Holes

For discharge machining of cooling air holes and shaped diffuser holes in blade and vane segments, Makino offers its EDBV3 fast-hole drill EDM.

Read MoreWire EDM Ensures Positioning Accuracy

The SL400Q wire EDM from Sodick features a rigid cast construction and a ceramic workzone.

Read MoreWire EDM Provides Higher Rigidity, Thermal Stability

Makino will spotlight its U3 wire EDM, which merges all machine components into a single base structure for improved mechanical rigidity and thermal stability.

Read MoreEDM Drilling Unit Improves Production for Aerospace Manufacturer

This shop utilized a hole-drilling EDM to improve setup time, manage labor hours and provide faster turnaround.

Read MoreWire EDMs Provide Fast, Automatic Wire Threading

Available from Absolute Machine Tools, the Accutex “Great Economy” (GE) wire EDMs combine high cutting speed and accuracy with automatic wire threading that provides fast submerged rethreading at the break point.

Read MoreWire EDM for Jet Engine “Fir Trees”

Advances in wire EDM (electrical discharge machining) technology have made it acceptable for machining critical aerospace parts. It may now become the preferred method for cutting turbine disc “fir trees,” a particularly demanding application that highlights the benefits of this machining process.

Read More