Cutting Tools

Metal-Bond Wheels Roll Toward New Horizons

Historically, metal-bond wheels have been perceived as too slow for jobs involving carbide tool blanks and other very hard substances. This shop's success using a specially formulated metal-bond wheel from Abrasive Technology to grind drill blanks calls this long-held notion into question.

Read MoreInserts for Static O-Ring Grooves

Thinbit, manufactured by Kaiser Tool Company, offers an addition to the Groove ‘N Turn line for machining static O-ring grooves.

Read MoreModular Connection for Large Boring Tools

The CKN modular connection for large boring tools features a three-screw interface, providing high clamping forces for maximum torque transmission.

Read MoreThe Progress of a Progressive Die Maker

This shop sees no long-term threat in the reality of lower prices. Machine tool investments related to various die components allow the shop to use skilled labor more efficiently.

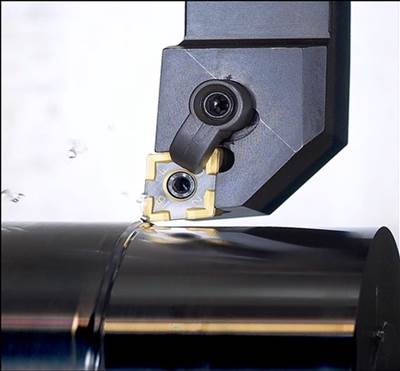

Read MoreSteel Turning Grade Increases Tool Life

Seco Tools’ TP3500 grade offers improved edge toughness and wear resistance in demanding applications that require long and consistent tool life.

Read MorePerformance Drills for a Variety of Materials

The HY-PRO CARB 3D and 5D drills from OSG feature point and flute geometry designed to reduce thrust forces and chip size, which enables higher feeds and metal removal rates.

Read MoreCatalog Features Tools For Increased Productivity

The 2010 full-color catalog from Imco Carbide Tool features case studies and user testimonials that include tips for increased productivity, sustained performance and extended tool life.

Read MoreVersatile Turning Geometry

ATI Stellram offers a versatile geometry for finish turning components ranging from steel to high-temperature alloys.

Read MoreTool for Shallow, High-Feed Cuts Speeds Roughing

“Feed fast, cut shallow.” This strategy, in combination with a cutting tool specifically designed to take advantage of it—the Power Feed+ from Ingersoll—enabled this shop to reduce cycle time on a tough prototyping job by a factor of five and increase insert life by a factor of six.

Read MoreWhen Spindle Speed is a Constraint

Though it won’t replace high speed machining, Boeing sees “low speed machining” as a viable supplement to higher-rpm machines. Using new tools and techniques, a shop’s lower-rpm machining centers can realize much more of their potential productivity in milling aluminum aircraft parts.

Read More

.png;maxWidth=300;quality=90)