Metal-Bond Wheels Roll Toward New Horizons

Historically, metal-bond wheels have been perceived as too slow for jobs involving carbide tool blanks and other very hard substances. This shop's success using a specially formulated metal-bond wheel from Abrasive Technology to grind drill blanks calls this long-held notion into question.

Share

Even as technology evolves to offer new, more effective approaches to particular manufacturing applications, some continue to cling stubbornly to proven techniques that have been accepted as conventional wisdom. Typically, only the most knowledgeable, dedicated and innovative manufacturers are both willing and able to "rock the boat" and take the first steps toward implementing new processes and procedures

According to Glen Rosier, one such shop is Latrobe, Pennsylvania-based Aggressive Grinding Services (AGS). Mr. Rosier is part of the business development team at Abrasive Technology (Lewis Center, Ohio), which supplied specially formulated, metal-bond grinding wheels to replace the resin-bond models the shop had used to grind carbide drills. The result was 70 percent longer wheel life and a 50-percent reduction in dressing cycle time.

This switch may seem counterintuitive to some. Historically, metal-bond wheels have been employed primarily in specialized applications such as grinding automotive windshield glass. While these wheels are much stronger than their resin-bond cousins, they are often perceived as too slow for jobs involving carbide tool blanks and other very hard substances, Mr. Rosier says. However, AGS’ success with the wheel supplied by Abrasive Technology calls these notions into question. The chemistry of the metal bond and the dispersion of the diamond abrasive enables the shop to take advantage of the wheel’s strength at speeds comparable to its previous resin-bond wheels.

However, the shop’s ability to apply the wheels effectively says as much about its grinding expertise as the technology itself, Mr. Rosier says. Despite the strides made by Abrasive Technology in the formulation of these wheels, their extreme hardness still makes them difficult to use compared to resin-bond wheels—which, he notes, is one reason why the latter models have gained widespread acceptance for tool grinding operations. "In my mind, AGS is one of the very few companies that really look to optimize every single operation. That’s why it can do such quality work and get it done quicker than everyone else," he explains. "Truly optimizing a product’s performance takes a coupling of the underlying technology and a customer that’s willing to learn to make that product perform."

AGS performs specialized grinding operations in carbide, ceramics, high-alloy steels and other hard materials for a variety of industries, including oilfield, automotive and aerospace. Virtually all types of grinding are performed here, including cylindrical, surface and centerless, as well as honing. High-end inspection and EDM equipment rounds out the 20,000-square-foot shop floor, where 64 employees work three shifts. The shop’s goal is to turn around all jobs within 24 hours, and consistently attaining that benchmark has led it to grow by approximately 20 percent per year since its founding by Lester Sutton in 1988.

Meeting such lofty ambitions requires not only ensuring top performance from the company’s machine tools and operators, but also keeping up-to-date with the latest technology. "I spend part of each and every day researching the most modern CNC equipment available to us," says operations manager Sam Sutton, who led his father’s company to purchase its first CNC machine when he joined in 1999.

Since then, the shop has invested in a number of CNC machines, including 29 OD and thread grinders from manufacturers including Rollomatic and Kellenberger. These machines are used to grind the points and back tapers of carbide drills for shipment to the customer, a cutting tool manufacturer that has only to machine the flutes in order to complete the tools. At AGS, the first process performed on the raw rods is pinch grinding on the shop’s Rollomatic NP4 cylindrical grinding machines.

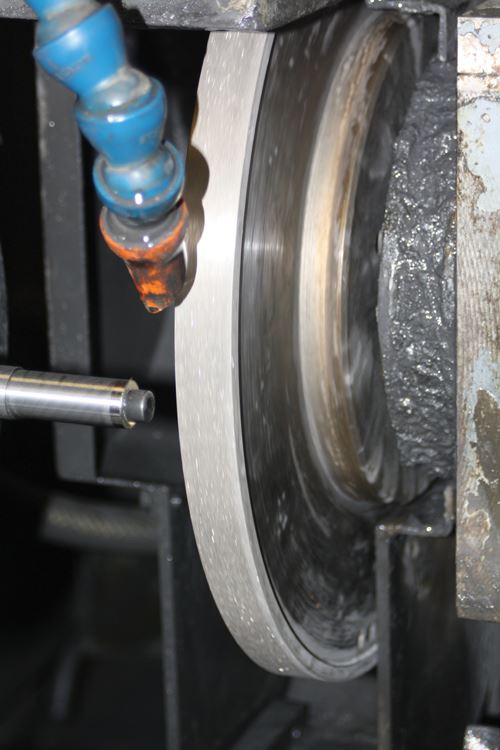

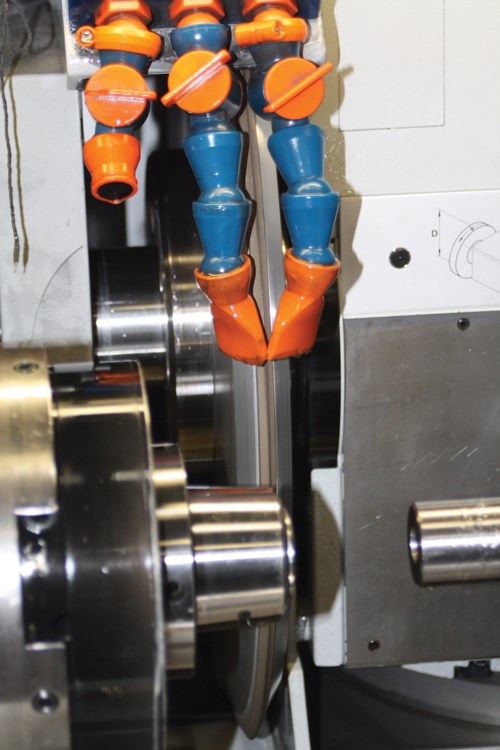

Developed by Rollo-matic (Mundelein, Illinois), pinch grinding is a form of peel grinding, a process often compared to turning in which a very narrow wheel is used to remove material. The difference is that pinch grinding simultaneously applies two wheels on either side of the workpiece to enable roughing and finishing in the same pass. Mr. Sutton says this process enables the company to reduce cycle time, improve concentricity and achieve surface finishes ranging from 2 to 4 RMS on the drill blanks.

However, the capabilities of even the most sophisticated equipment can be limited if some other element of the process has not evolved to the same level. In this case, the shop’s resin-bond wheels simply couldn’t withstand the demands of the machine parameters needed to turn around the tool grinding job fast enough for the shop’s liking. Operators frequently had to stop cycles for dressing and size adjustment, resulting in significant downtime and lost productivity. "The problem was that we couldn’t hold corner retention with those wheels," Mr. Sutton explains. "The corner would constantly break off, and we couldn’t keep the form we were trying to achieve."

Seeking a solution, the company consulted Mars, Pennsylvania-based distributor D&S Tool and Supply Company, which led them to Abrasive Technology. "They needed something that could grind just as fast as a resin-bond wheel, but would also be substantially stronger and tougher," Mr. Rosier explains. "Dr. Yefim Vernik, Abrasive Technology’s lead engineer, had spoken for years regarding the use of metal bonds with composite diamond structures to enable extraordinary grinding characteristics under extreme pressures. This opportunity presented itself as the ideal place to test his theories."

Dr. Vernik, who holds a doctorate in metallurgical engineering and a number of U.S. and Russian patents, came to Abrasive Technology from the Institute of Ultra-Hard Materials in Kiev, Ukraine more than 20 years ago. Mr. Rosier says Dr. Vernik’s theories pertaining to the shapes and sizes of diamond abrasive particles, and how those particles could be dispersed in a metal-bond wheel to increase performance, were ahead of technology available at that time. Now that has changed, especially through advances in the diamond industry. "Manufacturers today can produce crystals to sizes, shapes and specifications that are suitable for applications once thought impossible," he explains.

Initial testing at the shop showed that the new wheels’ tough metal matrix and tightly controlled diamond standards dramatically improved performance compared to the previous wheels without degrading speed. The company says this demonstrates that shops like AGS—that is, those with the expertise to properly condition these wheels and pair them with the right machines, coolant and other process elements—can spurn long-held notions about which applications are suitable for these tools.

Since implementing the wheels, the shop has been able to machine 1,000 parts per dress during operations on the NP4, as opposed to only 45 with the resin-bond wheels. "The resin-bond wheels were constantly breaking down, and we don’t have that sort of wear with the metal bond," Mr. Sutton says. He adds that in addition to reduced downtime, the stronger wheels have improved operator efficiency. With less frequent dressing and size adjustments, operators can run three to four machines at a time, as opposed to only one or two previously.

The company has since employed the wheels to improve productivity in other operations, allowing it to bring in new business. In fact, the wheels are now in use on more than half of the shop’s CNC machines. As an example, Mr. Sutton cites an operation involving intricate form work. "We tried it with a

resin-bond wheel, and we had the same problem—it just wouldn’t hold the corner," Mr. Sutton says. "The corner retention on the metal-bond wheels is so good that we can push in those intricate forms and hold a tight radius. Rather than doing it in multiple operations, we can do it in one."

Related Content

How to Accelerate Robotic Deburring & Automated Material Removal

Pairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreToolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.

Read MoreSelecting a Thread Mill That Matches Your Needs

Threading tools with the flexibility to thread a broad variety of holes provide the agility many shops need to stay competitive. They may be the only solution for many difficult materials.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)