Cutting Tools

Webinar: Increase Milling Output on Your Existing Machine

It is not always the strength of the tool or the power of the machine that limits your depth of cut. In many cases, the limitation is the tendency to vibrate. Learn how to mill more productively by selecting spindle speeds tailored to your machine’s dynamics.

Read MoreTangential Milling, Slow-Motion Video Address Slotting Bottleneck

By switching to tangential milling from Ingersoll Cutting Tools and using a slow-motion video to identify and overcome a lack of horsepower, Busche Enterprise was able to reduce cycle time and tool cost.

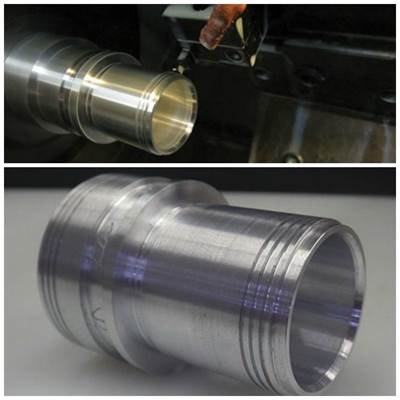

Read MoreThe Right Tools for Micro Grooves

Mack Tool and Engineering used modified inserts to create micro-grooves, but they were prone to breaking. After switching to Thinbit Groove ‘N Turn tools from Kaiser Tool, the company experienced increased tool life.

Read MoreIn the Groove for 50 Years

It’s an American success story. In 1964, William and Hazel Kaiser founded a company to produce and market Thinbit, an innovative line of grooving tools. At first, the business operated out of the couple’s attic and garage. Fifty years later, the Kaiser Tool Company’s products continue to help shops such as Mack Tool and Engineering with successful solutions for demanding grooving applications.

Read MoreLive Drilling System Precisely Controls Motion

The Live TriboMAM drilling system from M4 Sciences, featuring modulation-assisted machining (MAM) technology, is suitable for use with gun drilling machines and machining centers.

Read MoreFive Go-To Machining Technologies

There are a number of ancillary machine tool technologies that shops can use to become more efficient and effective. Here are five that I appreciate.

Read MoreDeep Holes with a Difference

Upgrading its deep-hole drilling capability with a Precihole three-axis machine from Absolute Machine Tools made a positive difference in this shop’s part processing, business strategy and customer service.

Read MoreCutter Promotes Chip Removal during Deep Plunging

Walter USA has expanded its Proto-max series of high-performance solid carbide end mills with the Prototyp Proto-max "Tough Guys" (TG) end mills, designed for use with steel, stainless steel, cast iron and super alloys.

Read MoreEnd Mills Enable Peel Milling, Trochoidal Techniques

The T‐Carb line of six‐flute high-performance end mills from SGS is designed for aggressive high-speed machining applications using peel milling and trochoidal techniques.

Read MoreTap Flute Design Promotes Chip Control

OSG's Exotap A-Tap series is designed to achieve better chip evacuation, especially during blind hole tapping.

Read More

.png;maxWidth=300;quality=90)