Cutting Tools

Milling Cutters Equipped with Through-Coolant

The Hi-FeedMidi family of high-feed milling cutters from Ingersoll Cutting Tools is based on the company’s Hi-FeedMini, but is capable of a 0.060" depth of cut.

Read MoreSteel Turning Grades for Transmission Manufacturing

Intended for large-batch production of transmission components, Sandvik Coromant’s GC4315 and GC4325 steel turning grades feature the company’s Inveio alumina coating technology and are said to offer high wear resistance and improved tool life.

Read MoreChipbreaker, Grade Offer Reliable Turning High-Temperature Alloys

Tungaloy has introduced the AH905 grade and HMM-type chipbreaker, specifically designed to optimize turning in high-temperature alloys.

Read MoreDeep-Hole Drills Avoid Pecking

Walter USA has added the Titex X-treme D40 and D50 to its line of solid carbide deep-hole drills.

Read MoreVideo: Trial Cuts with Ultrasonic-Assisted Machining

Ultrasonic-assisted machining reduces friction in metal cutting to enable a standard tool to cut faster and more smoothly. Video shows comparison cuts of the same machine and tool with and without this new accessory.

Read MoreCenterline Issues for Turning Inserts

Tooling experts Mike Fagan and David Grant suspect that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is their effort to clear up some of the misunderstanding.

Read MoreA Square Hole for a Square Peg

Putting square and rectangular boxes into wedge-shaped slots in a vending system isn’t the best use of the space. A tambour-style system with rectangular columns and adjustable shelving creates slots that better accommodate items with their packaging.

Read MoreInserts’ Smaller IC Reduces Carbide, Increases Productivity

Ingersoll has added two insert styles to its T-Tank product line: the WNMX and DNUX inserts.

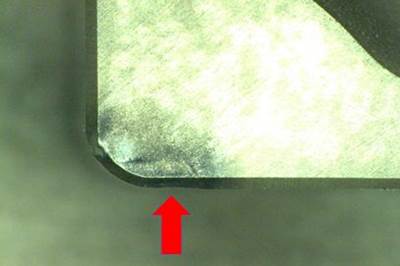

Read MoreCutting Insert Incorporates Through-Tool Coolant

The Horn HP65-grade S224 indexable insert with through-tool coolant features the company’s 3V geometry and a 3-mm (0.118") grooving width.

Read MoreThrough-Coolant Capability Reduces Cycle Time

Aided by Walter Titex tooling and a new higher-rpm machine tool from Fryer, Toolmasters Inc. was able to cut cycle time on a complex die set.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)