Five Go-To Machining Technologies

There are a number of ancillary machine tool technologies that shops can use to become more efficient and effective. Here are five that I appreciate.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

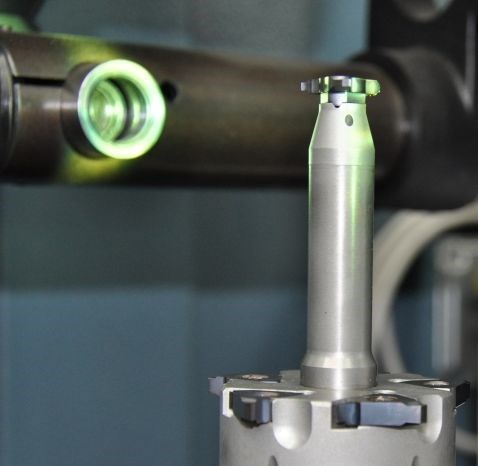

Toolholder assemblies for an upcoming job can be measured in seconds using a presetter, without the machine being interrupted.

We all know what opinions are like. That said, I thought of five pieces of ancillary machining equipment that I feel many shops can leverage to their success:

- Tool vending systems

- Tool presetters

- Machine tool probes

- High-pressure coolant delivery

- Shopfloor CMMs

Related Content

-

Choosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

-

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

.jpg;maxWidth=300;quality=90)