Deep Holes with a Difference

Upgrading its deep-hole drilling capability with a Precihole three-axis machine from Absolute Machine Tools made a positive difference in this shop’s part processing, business strategy and customer service.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Leese & Co. is deeply involved in deep-hole drilling. Although the company’s two locations in the Greensburg, Pennsylvania, area are home to many machining processes at which it is highly qualified, deep-hole drilling has been an area of specialized expertise and confidence that sets it apart from other suppliers. While many shops shy away from the challenges of deep-hole drilling, Leese & Co. has made it a mainstay in the range of capabilities needed to process a variety of demanding workpieces for diverse applications.

Maintaining this diversity is a key part of this job shop’s business strategy. “Getting tied too closely to one industry or one type of workpiece is limiting and risky,” says Christian Klanica, company president and owner. “Plus, a healthy mix of parts and customer applications keeps our skills honed and makes work more interesting.”

However, the company has built a reputation as a top-notch supplier of custom heat sinks and chill blocks, all types of which require high-precision deep-hole drilling. “It’s a niche in which we are particularly strong, but one of many options we offer for precision machining in prototype or production quantities,” Mr. Klanica says.

Because the company uses deep-hole drilling on a daily basis and was experiencing growth in orders for its line of custom chill blocks, upgrading its deep-hole technology became a priority in early 2013. The deep-hole drilling machine that had served the company well for 17 years was no longer able to provide the flexibility, efficiency and reliability the shop needed. As the company began investigating improved deep-hole drilling technology, the buying team was determined to keep an open mind.

This outlook led the team to consider offerings from a newcomer to the U.S. market, Precihole Machine Tools, a machine tool builder based in Mumbai, India. “We were willing to take this company seriously because their U.S. importer, Absolute Machine Tools, takes this product line very seriously. That gave us a lot of confidence,” Mr. Klanica says.

In October, Leese purchased an XY GVN 25/1-100 deep-hole drilling machine, the first machine from this builder installed in the United States. All aspects of this installation were handled entirely by the importer’s in-house service department. This machine provided significant advantages very quickly. “We can point to numbers that prove how valuable upgrading deep-hole capability has been for us,” Mr. Klanica says. “Saving more than 30 minutes of machine time per part is one example. What is more important is how we leveraged this new capability by creating a cell for chill block production and implemented a major change in the way we process this kind of part.”

In fact, strengthening its core capability in deep-hole drilling is leading the company to be more aggressive in attracting challenging jobs that require this expertise. “We have experience in deep-hole drilling of copper, aluminum and steel, so growing this part of our business is a top priority for the rest of 2014 and the years beyond,” says Jim Martz, sales manager.

Deep Across the Board

Founded in 1953, Leese & Co. is a family-owned and operated manufacturing company. Currently, it occupies two facilities located about one and a half miles apart on the outskirts of Greensburg, which is not far from Pittsburgh. The hilly, wooded area surrounding these facilities is a mix of rural and suburban settings. Perhaps the attractiveness of these environs helps account for one of the company’s traditional strengths—the number of long-term employees who are experienced machinists. Many of them have been part of the organization for 30 or more years, with a few individuals having worked at Leese for more than 40 years.

Another attraction for Leese employees is working with a variety of late-model CNC turning centers, VMCs and HMCs. The newest turning machines are equipped with live tooling; the newest machining centers are equipped with pallet changers. Not to be overlooked is an array of conventional equipment that represents traditional toolroom capability intermixed with the CNC machines.

Mr. Klanica feels strongly that companies like his need both depth in an experienced workforce and depth in up-to-date machining technology. He works hard to retain skilled craftsmen, offering a combination of a respectful management style and competitive compensation. The company also works with the local community college to recruit and train several apprentices each year, most of whom are fortunate to stay on as full-time employees when training is complete. The company works three shifts and typically has positions available for the talent it would like to retain.

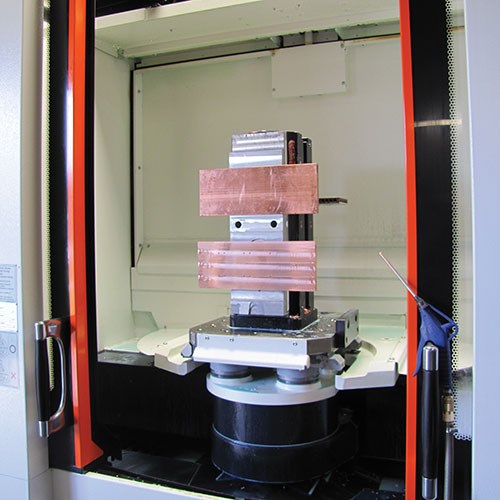

The majority of the CNC machines are in the original location, which is the larger of the two. The second building, occupied since 1996, contains sales and administrative offices, as well as an ample production area where the deep-hole drilling machines are located. A Mazak Nexus 4000-III HMC, the company’s latest machining center acquisition, is also located here, directly across from the new deep-hole drilling machine. For the chill blocks and heat sinks, these two machines can be operated as a single cell with one operator. The older deep-hole machine has been moved to the back of this shop area and is occasionally called into service for utility purposes.

Depth At The Sources

Precihole may be new to the United States, but it is not new to production of hole-finishing and deep-hole-drilling machines. The company has been providing such machines to India, South America, Europe and Asia for more than 25 years. Its products include deep-hole-drilling equipment (single- and three-axis gundrilling machines, BTA/STS drilling machines, and bore-trepanning machines), hole-finishing equipment (skiving, honing, reaming and lapping machines) and rifling machines (button rifling and cut rifling models).

Absolute Machine Tools (Lorain, Ohio) was appointed the exclusive U.S. importer for Precihole in July 2013. One of the most successful machine tool importers in the country, Absolute now represents a range of brands and machine types. Because it recognizes the importance of a U.S.-based staff to handle application engineering, service, customer support, training and preventive maintenance programs, Absolute was a good fit for Precihole as a leading Indian machine tool builder entering the U.S. market.

Mr. Klanica admits to having concerns about purchasing a machine with no established U.S. user base. These concerns were allayed by three factors, he says. The overall construction, fit and finish of the deep-hole machine compared favorably to other top-of-the-line machines from globally active builders. Likewise, many of the major components of the machine were from well-known U.S. or European suppliers, including Baldor for pump motors, Siemens for the CNC unit, SKF for bearings, Bijur for the lubrication system and Mayfran for the chip conveyor. Finally, the sales and service support from the importer were characterized by experience, professionalism

and responsiveness.

Early Results

Mr. Klanica reports that the new machine was installed in one day and running at full capacity within a week. “We expected the machine to reflect the fact that deep-hole drilling technology in general has made the kind of strides in productivity and quality that are apparent in other metalworking processes. But this model in particular proved to be especially well-suited to our needs,” he says.

Some of the general aspects of deep-hole technology that make this process part of a new era include higher-torque spindle motors, more powerful CNC features, better enclosures for cleaner operation, and more efficient coolant delivery and filtering. Some of the features that distinguish the new machine at Leese include faster and simpler programming at the machine for a lower learning curve for operators, retention of position coordinates in the event of a power disruption, a collet system that enables shorter setups and an internal load meter that stops the machine before tool wear can result in breakage.

The tool load monitoring system proved to be especially important. Concern about tool breakage forced the shop to be overly cautious and conservative in feeds and speeds with the older technology. Now, drills can be safely used at more appropriate and productive parameters. This enables the machine to take full advantage of its high-torque capability. That load meter monitors the current drawn by the drilling spindle. If the current draw (amperage) reaches a predetermined level, the machine detects the change and shuts down automatically to prevent damage to the tool or the workpiece. The threshold for machine shutdown can be programmed into the CNC logic, and the feedback is continuously shown on the control screen.

The more precise control of the drilling process and the stability of the machine structure also enable the shop to use off-the-shelf deep-hole drills, rather than tools with custom-ground tip angles on cutting edges that were tweaked for optimal performance on the older machine. On the new machine, standard drills can outperform the custom tooling formerly used by a factor of 3.5, and the shop expects the productivity gain to reach a four-fold improvement as it gains experience with parameter settings. The shop has used drills ranging from 0.1 to 0.75 inch in diameter.

Initial results with new deep-hole drilling technology have been impressive. For example, when drilling a copper part with five 12-inch holes, the shop saves 33.3 minutes of machine time. Whereas the older technology drilled these holes at 0.6 ipm, the new technology drills them at 0.9 ipm. With the older machine, a 12-inch-long hole in copper could be drilled in 20 minutes. With the new machine, that hole can be drilled in12.33 minutes.

Given an average of 48 copper chill blocks per order, the new machine enables 26.66 hours to be saved per order, a 30-percent reduction in machine time. Although the shop has processed fewer steel parts on the new machine so far, similar improvements have been recorded. For example, a hole in steel was formerly drilled at 0.7 ipm. The new feed rate is 1.5 ipm. With more experience and a strong continuous improvement culture, further improvements are expected to be forthcoming.

Processes Changes

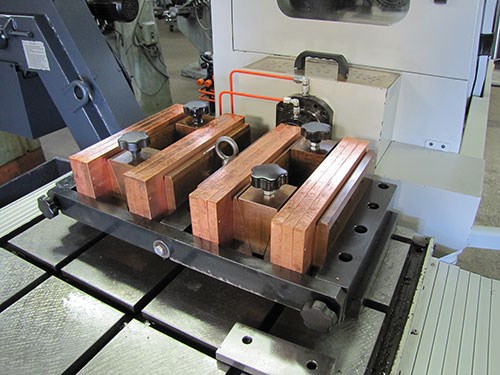

Mr. Martz attributes additional productivity gains to engineering input from Precihole’s factory. For example, it designed and built a custom fixture that enables workpieces to be set up in multiple gangs of three so that three pieces can be completed in one cycle before indexing. (The X-Y table provides precise positioning for processing of multiple part setups as well as prismatic workpieces). This capability had been demonstrated with prototype parts prior to purchase of the new machine. “We could anticipate and prepare for these results,” Mr. Martz recalls. “It also helped to streamline the training process.”

An important benefit of previewing machining results and evaluating the custom fixture was an insight into a basic process change involving the nearby HMC. Leese implemented a two-step process whereby the chill blocks are clamped two by two in vises mounted on tombstones carried by the pallet changer. In the first step, the blocks are squared with a face mill and then moved to the fixture on the deep-hole machine. After the lengthwise holes are completed, the blocks return to the HMC, where they are remounted in the same vises.

In the second step at the HMC, cross holes are drilled through the side of the blocks. Once this step is completed, plugs are welded into the appropriate side holes to form one continuous channel inside the block, thus enabling it to circulate fluid internally to remove heat in end-user applications such as marine drive transmissions.

Because the deep holes produced by the Precihole machine consistently hold tight tolerances for straightness, size and location, the results complement the accuracy of operations on the HMC.

Flexibility Runs Deep

Although custom heat sinks and chill blocks provide the most striking examples of how

advanced deep-hole drilling technology has benefited this shop, they don’t tell the whole story. “CNC control of the X-Y table makes it a very flexible machine for hole-making operations on prismatic parts, whether or not the holes can be technically classified as deep ones,” Mr. Klanica explains.

For example, he says the machine is ideal for producing bolt-hole circles or other hole patterns on the ends of long workpieces that would be difficult to process on standard machining centers. This flexibility enables the shop to drill bolt hole circles on the ends of aluminum spool valves for hydraulic applications. The spools required a 5.63-inch-diameter circle of six evenly spaced holes 0.625 inch in diameter. A similar application called for a pattern of fastener holes on the ends of long steel axle assemblies for railcars. Typically, the shop uses the same carbide-tipped drills and low-viscosity mineral oil coolant for “non-deep” hole-making operations.

Leese has used the new machine to produce coolant lines in steel mold bases, to drill lubrication holes for grease to reach bearing races deep within rotational assemblies, and for many other applications.

Today’s deep-hole drilling technology has the capability and flexibility to make it a mainstay for the diverse applications found in a broad-spectrum manufacturing company such as Leese. “We need specialized equipment for deep-hole drilling, and we have the skills to make it one of our specialties,” Mr. Klanica says. “But we use it so much that it has become an ordinary part of what we consider extraordinary service for our customers.”

Related Content

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

Read MoreHigh-Feed Machining Dominates Cutting Tool Event

At its New Product Rollout, Ingersoll showcased a number of options for high-feed machining, demonstrating the strategy’s growing footprint in the industry.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=300;quality=90)