CNC & Machine Controls

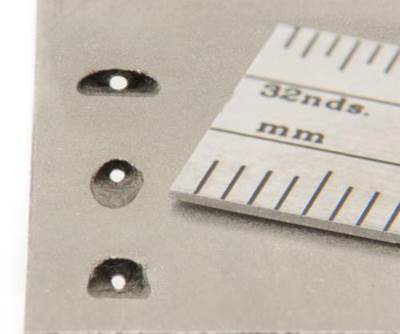

Control Software Eases Laser Drilling of Shaped Holes

Prima Power Laserdyne’s ShapeSoft, a feature of the SP94P control for its multi-axis fiber laser systems, simplifies the creation of programs for producing cone, oblique cone, fan, racetrack and a variety of shaped holes.

Read MoreImproving a Popular Mill-Turn Control

Gear hobbing capabilities, enhanced graphics and the ability to perform interpolation turning have been added to this well-known mill-turn control.

Read MoreLinear Encoder Protects Against Scale Contamination

Heidenhain’s redesigned Lida 400 series exposed linear encoders are designed for coordinate measuring machines (CMMs), linear motion stages, wafer inspection, waterjet cutting and other applications.

Read MoreVideo: Chatter Control in Spindle Speed Variation

Instead of running at a consistent speed, a CNC parameter enables the lathe’s spindle speed to automatically cycle up and down through a range. The process, therefore, spends only an instant at any problematic speed.

WatchHow a CAD/CAM Consultant can Help

This article from CNC Software (developer of Mastercam software) gives a good picture of why and when some shops turn to an independent software specialist for CAD/CAM services such as CNC programming of difficult or complex parts.

Read MoreControl Capabilities Often Go Unused

The value of some control capabilities don’t become apparent until they are seen in use. Heidenhain supports its CNC users with a new Chicago-area training facility.

Read MoreMarking System Controller Expands List of Compatible Equipment

Automator America has released the AC500 3.0 universal controller for its line of pneumatic, electric and scribe marking systems.

Read MoreOpen-Protocol Device Enables Connectivity for Legacy Machines

Mazak’s open-protocol, MTConnect-compliant SmartBox is intended to be a platform for secure entrance into the Industrial Internet of Things, designed to facilitate connectivity of machines and devices and enhance monitoring and analytical capabilities.

Read MoreDNC Box Enables CNC File Transfer via USB

Highland DNC’s ShopLink Flash USB-to-RS-232 adapter enables transfers of DNC program files to and from CNCs via flash drives.

Read MoreReal-Time Tool Monitoring

Machine operators have long dreamt of a process monitoring system that detects tool wear, and potentially catastrophic conditions and automatically compensates for changes in tool geometry after resharpening. Now that dream is a reality.

Read More

.jpg;maxWidth=300;quality=90)