CAD/CAM

NC-Checker For Machine Tool Verification

Using standard probing equipment, Delcam’s NC-Checker program verifies the in-process performance of a range of commonly-used machine tools. The program can be used before machining to confirm that the equipment has been set up correctly, and it also can be applied during the production run to detect any out-of-tolerance movements.

Read MoreToolpath Engine Available For Two-, Three-Axis Milling

Celeritive Technologies’ VoluMill 3. 0 toolpath software is a single-algorithm, high-performance toolpath engine that is designed to reduce programming and cutting time while increasing tool life.

Read MoreNew Technology Package For Milling Applications

Siemens Drive Technologies offers the Sinumerik MDynamics technology package for milling applications. The package combines CNC hardware, intelligent CNC functions and the complete CAD/CAM/CNC process chain for high-quality, high speed, precision machining.

Read MoreMulti-Axis CAM Generates Roughing, Finishing Toolpaths

Vero Software says its Machining Strategist v11 is a powerful multi-axis CAM solution that generates optimum roughing and finishing CNC toolpaths for both the office and shopfloor environment. The software is a CAD-independent solution that can work with data from various 3D modeling systems.

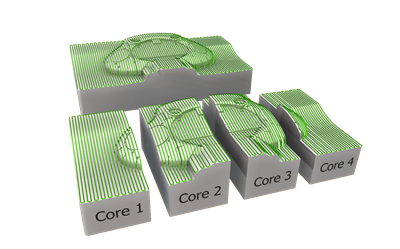

Read MoreParallel Processing Speeds Toolpath Calculations

Parallel computing refers to the division of programming tasks among multiple processors, or cores. Delcam says leveraging this technology has significantly reduced toolpath calculation times in the most recent version of its PowerMill CAM software.

Read MoreOptimized Tool Paths Save Time, Boost Profits

Faced with inefficient roughing operations on its stamping dies, foundry patterns and other aerospace industry tooling, this manufacturer sought to upgrade its CAM software. The Esprit CAM package from DP Technology helped reduce programming and cycle time by enough to generate a substantial increase in profits.

Read MoreUpdate To CAD, CAM, CAE Software

Vero Software’s VISI 17 features enhancements to the company’s CAD, CAM and CAE solutions. CAD enhancements include model thickness analysis, which allows the user to identify the thickest and thinnest areas of the model and validate its integrity.

Read MoreIntegrated CAM Software For SolidWorks

MecSoft Corporation, the developer of VisualMill, AlibreCAM, RhinoCAM and other computer aided manufacturing/CAM software solutions, has announced the release of VisualMill for SolidWorks, an integrated CAM software solution for SolidWorks users. The company says its partnership with SolidWorks unites its state-of-the-art, yet affordable CAM software solutions with CAD technology.

Read MoreCAE Software Optimizes Metalcutting

Third Wave Systems’ AdvantEdge FEM version 5. 4 is a materials-based software solution for the optimization of metalcutting.

Read MoreEnhanced Machine Simulation, Optimization

Vericut 7 from CGTech features enhancements designed to reduce the time required for manufacturing engineers to develop, analyze, inspect and document the CNC programming and machining process. Instead of focusing on new features or add-on modules, the company says it has focused on code optimization and customer-driven enhancements.

Read More