CAD/CAM

CAE Software Displays Results Visually

Third Wave Systems has releases version 5. 6 of its AdvantEdge Production Module, a process-analysis CAE software that integrates workpiece material properties, CAD/CAM inputs and machine dynamics to map forces, temperatures and more.

Read MoreCAM Suite Promotes Die Throughput

This automotive tool and die manufacturer had determined that remaining competitive would require reducing machining times. However, the impediment to throughput lay not in the machining end of the operation, but rather in the time spent programming complex tool paths. With fast calculation capability and a variety of strategies for five-axis roughing and finishing operations, Delcam’s PowerMill CAM package reduced programming times and enabled faster, more efficient machining.

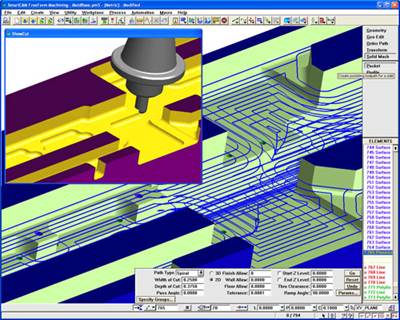

Read MoreGenerate Toolpaths Directly From Solid Models

SmartCAM V16. 0 from SmartCAMcnc includes automated toolpath generation directly from a solid model, additional solid model translation and improvements in visualization, verification and usability.

Read MoreInjection Molding Simulation Software

Vero’s high-end injection molding simulation software has been fully integrated with surface and solid modeling tools; comprehensive two- to five-axis machining strategies with high speed routines; two- and four-axis EDM; and a mold design package. Visi Flow 17 injection molding simulation software uses a custom hexahedral hybrid mesh technology to quickly provide accurate results, the company says.

Read MoreExpandable CAD/CAM With Built-In Learning Capabilities

The fully expandable VX 2009 CAD/CAM product from VX Corporation features Show-n-Tell, a built-in 3D learning system. These integrated 3D books allow users to learn CAD/CAM at their own paces and to grow the software as their needs change—all with instant access to learning tools.

Read MoreSoftware Enhances Functionality, Improves Productivity

Parasolid version 21. 0 from Siemens PLM Software features enhanced 3D geometric modeling functionalities that allow more complex changes during local edits of geometry.

Read MoreCAM For High Speed And Medical Machining Applications

CGS North America's CAD/CAM software, CAM-Tool Version 5. 0, is designed for mold and die machining.

Read MoreFast Mold Design, Machining

Delcam’s PowerShape CAD software and the PowerMill CAM system are said to offer fast mold design and fast machine tool programming, respectively. The fast mold design has been made possible by incorporating the Parasolid kernel for solid modeling alongside the company’s own surface modeling system.

Read MoreCAM Package Unlocks Turn-Mill Capabilities

While multi-spindle turn-mill machines can improve productivity by enabling users to machine parts complete in one setup, fully realizing their benefits requires a CAM package that is capable of synchronizing multiple spindles. With Delcam’s FeatureCAM software, cutting tool manufacturer Parlec eliminated the time-consuming process of programming each spindle of its turn-mill machines separately before manually synchronizing them on the shop floor.

Read MoreSoftware Aids Transition To Production Mindset

Over the years, aerospace manufacturer Costa Precision has developed a reputation for taking on large, complex parts that other shops can’t handle. However, overly optimistic customer expectations and lengthy cycle times led Costa to struggle with generating revenue on the manufacturing side of its business. With a new production-oriented mindset and CAD/CAM software from Mastercam, the shop was able to maintain the high precision for which it is known while improving manufacturing efficiency and profitability.

Read More