Optimized Tool Paths Save Time, Boost Profits

Faced with inefficient roughing operations on its stamping dies, foundry patterns and other aerospace industry tooling, this manufacturer sought to upgrade its CAM software. The Esprit CAM package from DP Technology helped reduce programming and cycle time by enough to generate a substantial increase in profits.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreNot all CAM systems are created equal. One differentiating factor is the efficiency of the toolpath strategies incorporated in the program. If these strategies are limited, operations on the machine might run at less than optimal speed.

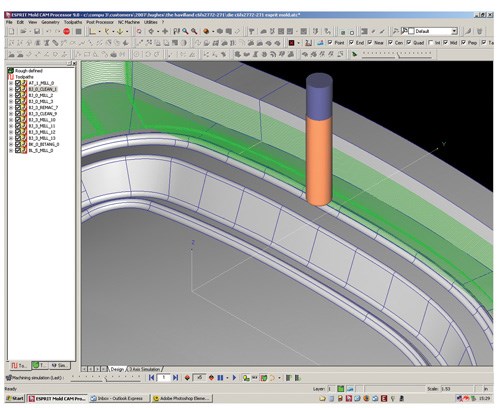

That was the case at Delta Pattern, a South Gate, California-based manufacturer of stamping dies, foundry patterns and other tooling, primarily for the aerospace industry. To improve efficiency, the company switched to a CAM package that optimizes roughing tool paths based on the results of previous machining cycles. According to the company, this and other features of DP Technology’s Esprit software have reduced cycle time on typical parts by 25 percent and programming time by 33 percent. As a result, profits have increased by approximately 30 percent.

Stamping dies produced at Delta Pattern are used to create parts such as aircraft doors and housings from aluminum, titanium and other materials. Sizes typically range from 10 by 20 inches to 3 by 4 feet, and most incorporate complex 3D surfaces. Depending on its complexity, machining time for a typical stamping die could range from 4 hours to 3 days. Typically, the company receives either an IGES file or a series of 2D drawings in the form of Mylar prints to define part geometry. Most dies and patterns are produced on a Johnford 2100H or a Haas VF4 machining center.

The company’s previous software worked well on parts composed primarily of 2D and 2.5D features, but it was less efficient for those involving the complex curves common at Delta Pattern. CNC programmer Abel Germán Olivieri says he was introduced to Esprit Mold at developer DP Technology’s 2006 World Conference, an annual user event. There, he learned that the CAM software package is designed specifically for companies like Delta that produce molds, dies, patterns, prototypes and other parts with complex 3D surfaces. "The key advantage of the software is that it offers machining strategies that minimize the amount of time needed to remove the large amounts of material required in this type of machining," he says.

Delta programmers begin by loading part geometry into the software. Next, they define the speeds, feeds, diameters, lengths, holder types and other such information for the desired set of roughing tools. The software automatically generates roughing tool paths based on this data. Programmers can choose to generate tool paths from outside-in or from inside-out, and a range of approach and retract positions are available.

Roughing proceeds by removing material from the workpiece in successive layers. The first paths use a relatively large cutter to remove as much material as possible. Then, to bring the workpiece closer to final geometry, progressively smaller tools machine areas of the model that were inaccessible to the initial cutter. For example, Mr. Olivieri says a typical milling operation might begin with a 2-inch-diameter bullnose end mill before moving successively to 3/4-inch, 1/2-inch and 1/4-inch square end mills.

To maximize material removal, Esprit determines how much stock each cutter can safely machine without gouging the part. Maintaining the same cutting depth to remove a uniform amount of material across each layer of the workpiece keeps tool loads constant and ensures efficient high speed cutting, the developer says. Additionally, the software continually monitors the in-process stock model via stock automation capability to track the location of remaining material at all times, even when machining undercut areas.

Mr. Olivieri says a key advantage of Esprit is that it automatically adjusts these roughing tool paths based on the results of previous machining cycles. In addition to reducing cycle time, this helps avoid air cutting while minimizing advance and retract movements. Other toolpath optimization capabilities include rounding sharp angles, smoothing stepovers and using trochoidal feed to enable climb milling in virtually any situation and to keep feed rates and chip loads constant.

The software’s high speed, Z-level finishing cycles, for which the shop typically employs ballnose end mills, are also characterized by smooth stepovers and the rounding of sharp edges for high speed cutting. Other features of these cycles include smooth, circular approach movements and the use of passes that vary in height to create a constant scallop height, contributing to quality surface finishes. The software also offers a Z-level zigzag strategy to improve cycle time and surface quality when machining vertical walls. In addition to rounding internal sharp edges for high speed cutting, this finishing cycle incorporates circular interpolation whenever possible to improve efficiency.

Delta programmers also benefit from Esprit’s feature-based capabilities, which enable them access the full functionality of solid models. The software automatically identifies part features and determines a logical order for machining operations. Programmers maintain the flexibility to change that order by simply dragging and dropping a feature to a different position on the sequence. This is especially useful if, for example, the software’s simulation capability reveals problems or opportunities for improvement. In that case, programmers can easily change or reorder operations to prevent crashes or reduce cycle time.

Also, programmers can create a knowledge base of optimized machining operations, each of which includes particular tools, speeds, feeds, cutting depths and other such parameters. The software automatically applies these operations when it encounters similar workpiece features. In addition to saving programming and cycle time for parts incorporating similar geometry, this ensures that the program takes full advantage of the shop’s machines, cutting tools and other equipment.

Support provided by DP Technology has been critical to the company’s ability to use the software successfully, Mr. Olivieri says. At first, the developer worked closely with Delta to identify its programming needs and provided on-site training. The two companies continue to communicate frequently via phone and e-mail, and Mr. Olivieri notes that technical support staff is responsive and willing to take the time to help the shop work through any problems. The developer also provided postprocessors for Delta’s machines, eliminating the need to edit G code.

"A typical stamping die that might have taken 12 hours to program in the past can now be programmed in only 8 hours," Mr. Olivieri concludes, noting that optimized re-machining and other software features have significantly reduced machining time as well. "These time savings provide substantial cost savings—they have helped to improve our profitability by 30 percent."

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreCan ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)