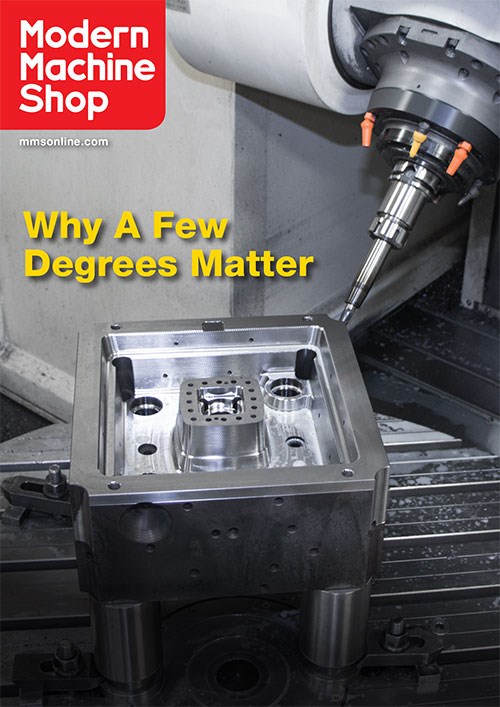

Why a Few Degrees Matter

3 + 2 machining might not be as captivating as five-axis contouring operations, but it can be just as valuable.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

Five-axis machines enable two types of multi-axis machining operations: full contouring and positioning (a.k.a. 3 + 2 machining). Thought of as siblings, contouring would be the alluring one and 3 + 2 would be more on the homely side. This is because contouring operations feature complex simultaneous motion of all five axes during a cut while 3 + 2 only uses the rotary axes to position and then lock the tool and/or workpiece at different angles outside of the cut.

That said, many shops find great value in 3 + 2. One is Canada’s Moulexpert. It now leverages 3 + 2 to manufacture more reliable and effective molds for thin-walled containers. Among other benefits, this capability has enabled it to reduce setups of mold inserts from as many as 25 to two, as detailed in this story.

Related Content

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

-

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.