Why Machine This Boxy Part on a Lathe?

South Morgan Technologies has long thrived on its ability to mill boxy parts on a turning platform. Today, newer technology and techniques enable saying “yes” to more work than ever before.

Share

A garage, a mill and a lathe. These are common elements in the origin stories of many manufacturers profiled in this magazine over the years, since before handwheels and tape readers gave way to CNCs. However, the lines between machine functionalities have blurred in recent decades. Consider the case of Kevin Ames, who began his own shop-in-a-garage origin story in 2011 not with two machines, but one: a 1996-model turning center with Y-axis live tooling.

Granted, it wasn’t long before Mr. Ames purchased a dedicated milling machine as well. Nonetheless, there’s good reason why a flexible turning platform was his first priority. Anticipating his role as production manager, machinist and shopfloor hand—not to mention salesman, accountant and janitor, to name a few others—he knew that time and resources would be limited, and that versatility would be key to success. “You generally can’t do any turning on a milling machine,” he explains. “With a turning machine, you don’t have to spend a whole lot more to start drilling holes, too, and a Y-axis will enable you to make some parts complete.”

A lot has changed in five-odd years. Having outgrown the garage, South Morgan Technologies now occupies a 6,000-square-foot leased space in Girard, Pennsylvania, where five total machine tools provide more processing options than ever before. And although Mr. Ames regularly gets his hands dirty, a staff of three leaves him with more time to focus on running the overall business. Nonetheless, this small contract manufacturer’s capacity to make the most of its resources and adapt nimbly to ever-changing shopfloor realities remains rooted in its capability to mill on a turning platform. The difference is that the shop is now leaning on a more capable platform, one that drives a greater variety of live tools at higher power and faster speeds while leveraging a subspindle to consolidate setups even further.

With a more versatile machine, the team at South Morgan is finding it easier to get creative and to say “yes” to more work than ever before, he says. Among other keys to turning on that creativity, Mr. Ames cites the right tooling and options, making the most of offsets, and treating every setup like a puzzle to solve, often through the use of machinable pie jaws.

More with Less

This turning center isn’t the shop’s most productive machine, points out Mike Lueck, plant manager. At least, not in terms of raw numbers of parts produced during any given time period. It isn’t the newest, either. Both of these honors go to a Genos M560-V three-axis VMC from Okuma America, purchased last February to complement a 1989-model CNC milling machine. That old workhorse is still running, and it is still more than capable of holding the ±0.001-inch tolerances typical of most of the shop’s work. However, the older machine’s days are likely numbered. And if the recent past is any indication, the future of South Morgan will involve a lot more milling, particularly in difficult materials like titanium. Even now, some parts demand too much horsepower for the shop’s two live-tool lathes, and the Genos is far more productive than the older mill, Mr. Lueck says.

Still, it’s telling that the shop maintained only one dedicated (and aging) milling resource through multiple advances in turning center and turning center milling capability over the years. It’s perhaps even more telling that Y-axis turning centers handle more unique jobs than the VMCs, despite the latter machines’ advantage in raw number of parts produced. After all, driven-tool lathes can often provide more efficient machining options than traditional three-axis milling strategies, Mr. Lueck says. When that’s not the case, less-aggressive cutting can make them a viable alternative to an occupied mill. For South Morgan, operating in this way helps stretch productive capacity (and financial and human resources) as far as possible in an environment where anything more than 50 parts is considered high volume. “Even if we quote what’s obviously a milled part, that doesn’t necessarily mean it’s going to go on a VMC,” Mr. Ames adds. “If there are any round features, and we have enough speed and power and tooling for the milling, we’ll usually do whatever we can to put it on a lathe.”

The shop’s newest turning center ensures that this approach will likely remain critical to stretching capacity well into the future, he says, even amid the active pursuit of more VMC work. Installed in March 2014, this Okuma LB3000EX-II horizontal lathe features the shop’s first subspindle and backworking live tools, which enable working both sides of a part in one setup. It can also take beefier cuts in more difficult materials than the shop’s other live-tool turning center, a year-2000-model Okuma LB300-M that drives tools at 4.4 hp (continuous) versus the new machine’s 7.5 (peak hp ratings are 9.5 and 10, respectively). “We’ve driven 5/8 taps in 316 stainless with no problem,” Mr. Ames notes. Meanwhile, driven-tool speeds ranging to 6,000 rpm (the older, non-subspindle machine offers 4,500) facilitate the use of both smaller and higher-quality tools that enable more precise, more intricate milling.

Making It Work

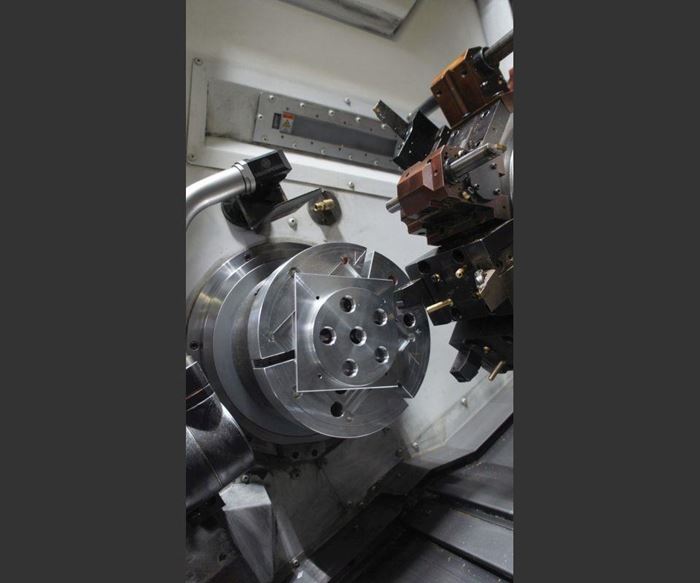

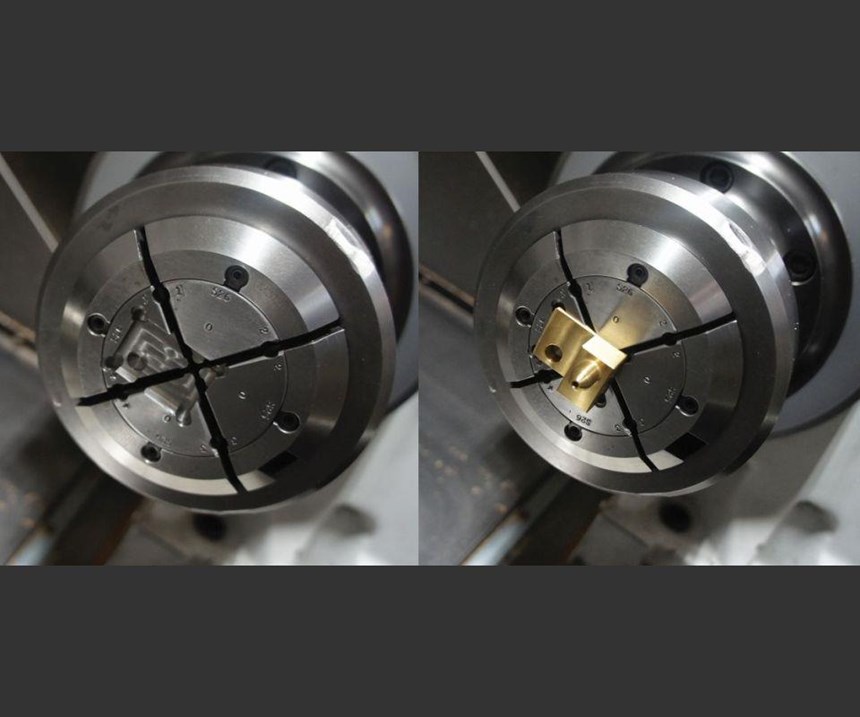

Although every job is different, one strategy is common to virtually all boxier geometries produced on a turning center: using machineable aluminum chuck jaws to clamp virtually any part-periphery shape. Even if a part requires no turning at all, indexing the lathe spindle (or subspindle) can present different faces to the Y-axis turret without refixturing. That said, leveraging a turning machine’s primary function is always a goal, and Mr. Ames and Mr. Lueck specifically seeks out rounded geometry when evaluating any potential new job. Custom jaws enable orienting work to keep these features on center—that is, aligned with the middle of the chuck and the machine’s Z axis—so that they can be turned.

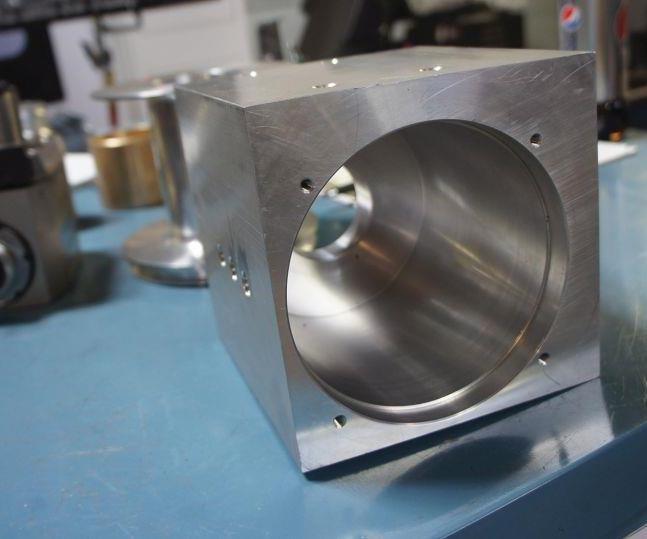

Consider the part on the cover of this magazine. One of two mating, rectangular components, it was initially quoted for a two-setup VMC operation but moved to the LB3000EX-II because the VMC was occupied, Mr. Ames says. After facing, profiling, drilling, tapping and chamfering operations, the roughly 6-by-6-inch workpiece was flipped over and remounted, this time in a separate, overlapping jaw profile machined at a 45-degree angle to the first (a clearance issue prevented the obvious approach of handing the part off to the subspindle instead). This second setup put the part’s off-center, round geometry at the center of the chuck for turning.

However, this approach would have been more difficult if the rounded boss stuck out much farther, Mr. Lueck says. That’s because an out-of-balance setup can create a wobbling effect as the spindle turns. The extra vibration impacts the workpiece long before it affects spindle bearings or other machine components (barring a part flying out of the chuck), but of course the South Morgan team strives to avoid adverse effects on either. To that end, stick-outs longer than three times diameter generally aren’t tolerated, and machining parameters for longer parts are often conservative. Another common approach is bolting additional material onto the jaws or machining some away to compensate for off-center part mountings.

Beyond these go-to strategies, Mr. Ames says it’s all about putting together the pieces of the puzzle that each job becomes when capacity must flex as needed to keep machines occupied and profits in the black. In cases when turned features are offset from workpiece center by a considerable distance, performing a significant portion of the milling work first might help balance things out. Similarly, “pre-roughing” a turned feature with live tools might temper some of an off-center part’s pull against the chuck jaws. “We might mill (a turned feature) into a shape like a stop sign first,” he explains. “Then, when we go in with a turning tool, the interruptions are less severe.”

Tooling Up Right

However creative, a machinist is limited at some point by the capabilities and processing options on the shop floor. Beyond a subspindle and greater speed and power, plenty of tooling was a top priority for the shop’s newest Y-axis turning center, Mr. Ames says. Eight live toolholders, four axial and four radial, offer a variety of processing options, although most jobs require fewer than that. The shop invested significantly in the tools themselves, too, outfitting the lathe (and in some cases, other machines) with a fresh package of cutters from Sandvik Coromant that are better suited for its speed and power.

Versatile tooling is a particular priority for the light, fast milling passes favored at South Morgan. Five-flute, 0.5-inch-diameter end mills with corner radii rounded off to 0.03 inch to prevent edge breakdown are standard for almost every milling operation that doesn’t involve aluminum, which favors a bigger, three-flute bite, Mr. Ames says. Tools can also be leveraged in multiple ways when necessary. For instance, a chamfer might be machined with a spot drill instead of a chamfer tool if the application calls for more tooling than can be mounted in the machine. Similarly, relying more on boring tools to reach final hole size is considered a small sacrifice for stocking fewer drills in larger-diameter increments.

Extra offsets have also been critical to leveraging the tool turret’s full capacity. One reason is that two of the axial toolholders are double-sided, enabling the same turret station to work on both main and subspindle. These stations require offsets for two tools, not one, and each tool is commonly associated with multiple offsets. Consider a simple grooving operation. For anything wider than the tool that machines it, the IGF conversational programming system that the shop purchased with the machine’s THINC OSP P300L CNC automatically assigns two offsets to opposite corners of the tooltip, one for each side of the groove. Controlling the position of each wall independently reduces the risk of a single offset leaving one side of the groove within tolerance and the other out of specification. In a more complex operation involving particularly sensitive finishing, the right combination of offset slots can enable a single tool to leave different levels of stock on different areas of the workpiece.

Certain offset slots are never overwritten, remaining linked to specific tools, Mr. Lueck adds. That way, if a tool is removed from the turret, it (or another of the same make, model and size) can be replaced without any additional measurements. Granted, he emphasizes that this works only for simpler tools, most notably drills (unlike, say, a grooving tool, a drill cuts at spindle centerline and is relatively forgiving in terms of precision). Nonetheless, this strategy saves time by making it fast and easy to re-install a drill that had been temporarily replaced by a more specialized cutter.

Static turning tools can also be doubled up on individual turret stations, one right above the other (say, a rougher and a finisher). That’s thanks to the machine’s optional offset turning function, which enables turning at Y-axis offsets other than zero. Via a slight Y-axis adjustment, the second tool can move in to the work right after the first. This saves a tool slot and eliminates the need to index the turret. This function is particularly useful during threading operations, Mr. Lueck says, explaining that a slight Y-axis offset can “make a world of difference” in tool life by applying additional, chatter-reducing load on longer parts that are subject to flex. Mr. Ames adds that the function might someday come in handy as a stop-gap if the machine were somehow knocked out of alignment.

Turning to New Programming Options

Conversational, shopfloor programming has always been the way at South Morgan Technologies. After all, writing 200-odd part programs per year would be far more time-consuming with a CAM package than with Okuma’s IGF system and its graphical, step-by-step interface, Mr. Ames says.

Even so, offline programming has recently found a home here as well. Based on trial-cutting results, the shop purchased a seat of SolidCAM high-speed milling (HSM) CAM software along with its new Genos M560-V VMC. The software has increased milling productivity through significantly higher machining parameters and more efficient toolpath strategies, he says. With this system in action, employing the same HSM software on the LB3000EX-II turning center has become a tempting proposition as well. The CAM developer’s turning package promises similar gains.

This isn’t to suggest that South Morgan would abandon conversational programming if it does indeed dive deeper into CAM software. Offline programming of the LB3000EX-II would provide yet another option for this evolving shop, an option that could further that evolution by facilitating faster cycles on more complex work. Meanwhile, a quickly drawn-up conversational program will always be superior in some cases—say, completing emergency work on the subspindle while another job runs in the main spindle.

Just as conversational and CAM each have their place, it’s important to keep in mind that a shop’s success with one type of machine tool shouldn’t be taken as a universal endorsement over other processing options. For instance, it’s not hard to imagine a rotary-fourth-axis VMC making a significant impact on the shop’s approach to quoting and machining at any point in its history, had it ever opted to go down that road. What’s more, no one can fully predict future needs. For his part, Mr. Ames says he didn’t fully anticipate the pace of the shop’s recent plunge into more advanced milling even as he pursued that very goal. Versatile machining turns not only on versatile technology, but also on creativity—on the drive and the ability to make the most of whatever resources are available.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More