Automation

Competing With Automation

Who would have guessed that an electrical discharge machine could work so fast that it would need a robot to keep it busy when everybody had gone home for the day? Who would have guessed that mold making, the epitome of skilled craftsmanship in metalworking, could lend itself to some of the most advanced automation in manufacturing? Who would have guessed that molds could be designed with so many cavities and inserts that all the electrodes and components needed to produce such molds would multiply and multiply and multiply? Who would have guessed that completing a complex, high quality mold in one half or one third of the normal time could be the new standard for mold work around the world? Who would have guessed that workers in mold shops overseas could be so talented, well trained and well equipped yet paid so little? Quite a few mold shop owners and managers in our part of the world did guess right about these things. They figured out what was happening years ago.

Read MoreAutomatic Pallet Systems Increase Production And Quality

These pallet changer systems not only improved this tooling manufacturer's labor situation, but they managed to increase their production as much as 600 percent on some of its indexable cutting tool products.

Read MoreMulti-Station Repeatability Enhances Quality For Complex Parts

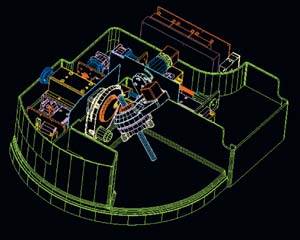

Flexible automation is making production machining a new opportunity for shops that traditionally did not seek this kind of work. At the same time, automated machining systems are taking new shapes and configurations that favor this trend. A recently introduced example is the Turn 6 LC from ATS.

Read MoreIs It Time For Bar Fed Machining Centers?

When we think of bar feeders, usually they are associated with turning operations. Recently though, some builders have developed machining centers that incorporate bar fed raw stock. It’s an interesting idea for the right applications and one that can economically reduce material handling and fixturing requirements on machining centers. Here’s a look at how they work.

Read MoreA Brief Update On CAM Software Automation

A continuing objective for CAM software suppliers is to enhance the ease of use and level of automation, even as additional functionality is being introduced. As such, the evolutionary march toward further automation of the NC programming function continues.

Read MoreAutoloading For Short Runs

Not too long ago, automatic load-unload was strictly for long production runs. Here is a system that makes it cost effective for short-run turning.

Read MoreProcessing The Process

The high speed horizontal machining centers in this manufacturing cell represent a very efficient process for machining cast iron transmission cases. How the crew runs and maintains this cell represents a very efficient process for making this cell ever more productive and cost effective.

Read MoreMulti-Axis Drill Sharpening Made Easy

Today, metalworking is privy to some very remarkable performances by the combination of things mechanical and things electronic--mechtronics. We've seen the reality of lights out shift operations. Programming systems that make what was state of the art 5 years ago seem like writing with a hammer and chisel. An example of the melding of mechtronics is this new drill sharpening system.

Read MoreReinventing The Robot For The Job Shop

A compact robot that rolls out of the way when not needed/wanted provides the perfect solution to this shop's automation needs.

Read MoreManufacturing Cell Boosts Profits And Flexibility

One machine shop owner in old New England, not far from where Paul Revere made his famous ride, saw a tight labor market as a call to revolutionize his company.

Read More

and Robin Schrager.jpg;maxWidth=400;quality=70)