Additive Manufacturing

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

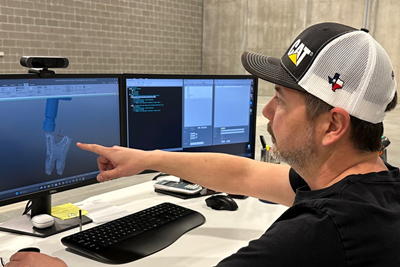

Read MoreDigital Transparency in Machining Key to Multi-Site Additive Manufacturing

Cumberland Additive’s CNC programmer in Pennsylvania spends most of his time writing programs for machine tools in Texas.

Read MoreLincoln Electric Partners With Bechtel Plant Machinery to Support US Navy

Lincoln Electric will 3D print large-scale propulsion components measuring almost 10 feet in diameter and weighing up to 20,000 pounds.

Read MoreRenishaw System Reduces Metal AM Build Times

A new scanning algorithm for Renishaw’s RenAM 500 series of metal additive manufacturing systems enables the laser to fire while the recoater is moving, which over the build cycle can reduce total build time by up to 50% with no reduction in part quality.

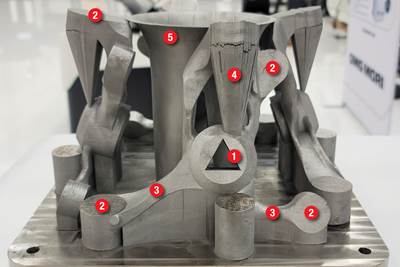

Read MoreDesigning a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

WatchRenishaw AM System Features Detailed Build Insight

The RenAM 500 Ultra system features innovative optical, chamber and gas-flow design, and also adds new productivity-boosting Tempus technology and advanced process monitoring software.

Read MoreSiemens Expands Additive Manufacturing Initiatives

The company has added new AM technology to its Charlotte Advanced Technology Collaboration Hub and plans to establish an AM advisory board.

Read MoreJTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read More