Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Share

Machining can be an obstacle in the quest for “first-time right” 3D printing — designers need to ensure parts can be held in the machine tool, and that machines can access the features and critical surfaces that need to be machined. The digital thread can aid in this by connecting designers with machining simulations, so they can adjust the part accordingly.

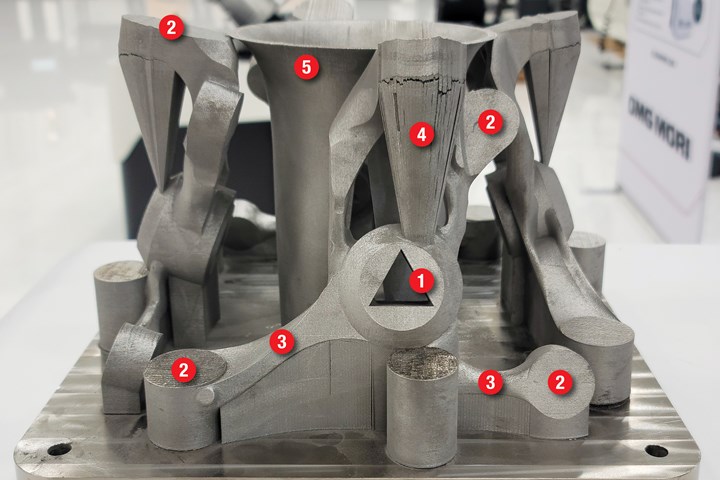

Adam Hiller, additive manufacturing and Siemens Xcelerator portfolio solutions consultant at Siemens Digital Industries Software, designed this 3D printed steering knuckle for an eRod (electric dune buggy) from Kyburz using Siemens software solutions connected by the digital thread. “We’re thinking of the entire lifecycle now instead of just saying, ‘Oh, the part looks cool, it does what we want and it will satisfy all our criteria,’” he explains. “We're saying, ‘Let's also make sure that everybody else downstream is able to do as automated of a process as possible.’” Here are several features on the as-printed part that were designed with machining in mind:

- Triangular mounting feature in center spindle hole. This triangle within what eventually became the spindle hole served as a mounting feature, and was eventually milled out.

- Extra stock in bolt holes. The four bolt holes were also machined (instead of printed) to ensure quality and precision at the points where the part attaches to the vehicle.

- Extra stock on critical surfaces. Designers added extra stock to the sections of the part that make contact with the vehicle. These areas were machined to ensure a flush fit.

- Machinable support structures. Support structures in metal 3D printed parts serve the important functions of holding up overhanging features and distributing heat away from the part to prevent warpage. Once the part is out of the printer and support structures are no longer necessary, they are typically removed by hand or machine tool. Hiller wanted postprocessing for the steering knuckles to be as automated as possible, so he ensured that the machine tool could access all of the support structures for removal.

- Trumpet mounting feature. While simulating the machining process, machinists realized the parts were at risk of being ripped off the build plate due to vibration. Hiller worked with the machinists to create a trumpet-shaped structure in the middle of the build plate to securely mount the parts for machining.

To learn more about how Hiller and his team used the digital thread in this application, read “Digital Thread Enables First-Time Right 3D Printing.”

Related Content

-

JTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Go Digital: How to Succeed in the Fourth Industrial Revolution With Additive Manufacturing

The digitalization of manufacturing is set to transform production and global supply chains as we know them, and additive manufacturing has been leading the way in many industries.