Five-Axis

Spotlight Slideshow: Machining Centers

Automatic pallet changers and support for automation are some popular features of recently released machining centers. View the December slideshow for more on these machines.

Read MoreFive-Axis Machining Center for OEMs, Job Shops

Available from Methods Machine Tools, the Methods-Yasda PX-30i is a five-axis high-precision automated vertical machining center designed to meet OEM and job shop requirements.

Read MoreFive-Axis Universal Machining Center

The Doosan FM 200/5AX Linear is a high-speed, high-precision, full five-axis machining center designed for simultaneous five-axis contouring.

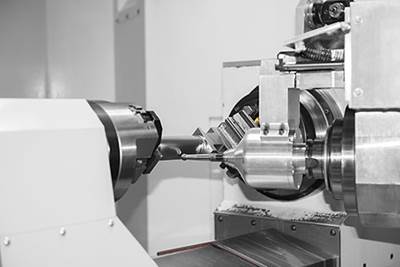

Read MoreApplying “Dengeling” to Finish Turbine Blades

This alternative to grinding, polishing and shot peening enables turbine blades to be machined and finished on one five-axis machine in one setup.

WatchTool Monitoring for Multitasking Machines

Continuously checking the condition of cutting tools and responding appropriately to wear or other changes is especially critical on machines designed to complete parts in a single setup or run several operation simultaneously.

Read MoreFive-Axis Machine Offers High Dynamics for Complex Workpieces

The Heckert HEC 800 X5 MT five-axis machining center, available from Starrag, provides productivity, process reliability and precise cutting in a single clamping.

Read MoreClamping Options for Five-Axis Machining

In five-axis machining, the workholding has to get out of the way. The wrong choice of clamping risks collision and can obscure one of the principal benefits of a five-axis machine.

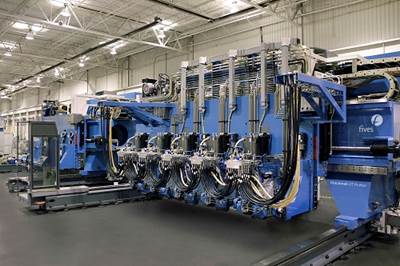

Read MoreProfiler Expected to Exceed 100 Cubic Inches per Minute in Titanium

Five-axis, five-spindle machine aims at reduced cost per piece for production of large aircraft components.

Read MoreA Novel Modular Clamping System

This clamping system minimizes setup times, enable a machine to access five sides of a part and provides highly repeatable positioning for bulky components.

Read MoreFive-Axis Machining Center Features Adjustable Work Envelope

Available from Methods Machine Tools, the Yasda H40i high-precision five-axis machining center is designed for improved repeatability and accuracy, tighter tolerances, and shorter cycle times for aerospace, die/mold and automotive manufacturing.

Read More