Siemens Monitoring Platform Integrates Samotics ESA

Using ESA technology, NXpower Monitor enables the detection of electrical and mechanical faults up to five months before downtime happens.

Share

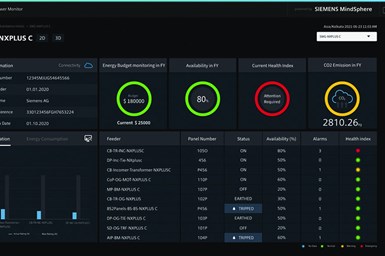

Siemens Smart Infrastructure has integrated electrical signature analysis (ESA) from Samotics into the NXpower Monitor, its digital platform for electrical networks. Using ESA and machine learning, Samotics provides real-time insights to help users eliminate industrial energy waste and unplanned downtime. This new capability leverages Siemens Xcelerator, an open digital business platform that enables customers to accelerate their digital transformation easier, faster and at scale.

The NXpower Monitor enables the visualization and monitoring of electrical assets within electrical networks, providing health statuses, key performance indicator (KPI) calculation, energy monitoring and monitoring of operational data from assets. This asset monitoring system is said to enhance efficiency and risk management across the entire energy distribution network through continuous health monitoring, while minimizing CO2 emissions and operating expenses. By integrating AI-powered ESA technology, Siemens broadens its application to include the monitoring of AC motors and rotating equipment, all accessible through a single pane of glass.

Using ESA technology, NXpower Monitor conducts real-time analysis of high-quality current and voltage data, enabling the detection of electrical and mechanical faults up to five months before downtime happens. Furthermore, the system delivers comprehensive performance and efficiency insights, pinpointing areas with the highest electricity consumption, cost, and efficiency losses. By implementing data-driven recommendations, organizations can optimize operational processes, significantly reducing energy waste and cutting CO2 emissions by up to 15%.

Stephan May, CEO of electrification and automation at Siemens Smart Infrastructure, says, “The digitalization of energy distribution, automation systems and networks brings many advantages. Not only does it lead to substantial savings in terms of time and money, [but] it also significantly boosts efficiency and reliability.”

Related Content

-

Reinventing a Precision Shop With a Data-Driven Mindset

When this machine shop lost 90% of its business within three months, a reinvention was in order. Here's how it survived after quickly falling on hard times.

-

Manufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

.jpg;maxWidth=300;quality=90)