Siemens Manage MyMachines Offers Entry-Level CNC Machine Monitoring

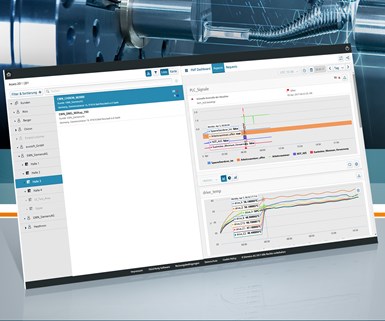

Siemens’ Manage MyMachines is a cloud-based platform as a service enabling full tracking of machine kinematics as well as production data.

Share

Siemens’ Manage MyMachines, one of the MindApps within the Mindsphere concept, is a cloud-based platform as a service enabling full tracking of machine kinematics as well as production data. The platform is marketed by Siemens as an entry point to shop digitalization. Machine shops and production departments, in conjunction with their system integrators and other business partners, can benefit from the platform’s transparent display of all CNC equipment on the floor regardless of location, brand, function or usage.

Manage MyMachines provides access to critical machine tool information, from bearing temperature to production by shift or job, scaled based on user needs. Unexpected line downtimes and off-normal machine kinematic conditions can be quickly identified and rectified. Predictive maintenance can be programmed such that an upcoming failure can be anticipated, with alerts sent, for example, to a local distributor for delivery of needed components.

Related Content

-

Give Job Shop Digitalization a Customer Focus

Implementing the integrated digital technologies and automation that enhance the customer's experience should be a priority for job shops and contract manufacturers.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

.jpg;maxWidth=300;quality=90)