Porta Solutions Machining Center Reduces Energy Costs

IMTS 2024: Porta Solutions introduces the Portacenter 400, an independent three-spindle machining center intended to enhance flexibility, production and cost-effectiveness.

Share

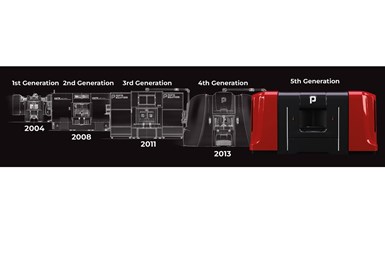

Porta Solutions North America Inc. displays the fifth-generation Portacenter 400, an independent three-spindle machining center. According to the company, the machine sits between traditional machining centers and transfer machines, so it is said to provide quick production while maintaining flexibility. The machine can reportedly machine over three times faster than a typical machining center, reducing labor, automation and part costs, as well as space and energy consumption.

The Portacenter 400 is mass-produced with lead times ranging from 60 to 90 days. The company also has a demo Portacenter machine to perform demonstrations, tests and training.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

.jpg;maxWidth=970;quality=90)