Esprit from DP Technology Gets Added Probing Cycles

DP Technology has added a suite of probing cycles to Esprit CAM software.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

ECi Software Solutions, Inc.

Featured Content

View More

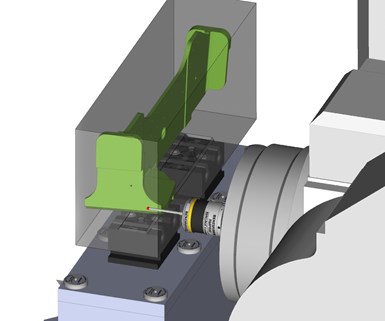

DP Technology has added a suite of probing cycles to Esprit CAM software. The new features include:

- Offline inspection programming, which enables virtual simulation for program verification and collision detection

- Hassle-free postprocessing and full control over each probing routine

- Compatibility with more CNC machines and probe manufacturers

These capabilities join the probing cycle’s existing features, including:

- Misload detection, which confirms correct part loading and reduces the risk of damage

- On-machine inspection, which generates consistent measurements and eliminates manual measuring errors

- Dynamic tool offsets, which automatically adapt the program considering tool wear

Using Esprit for CNC machines equipped with touch probes will contribute to increased throughput on existing equipment while reducing operator intervention, the company says.

Related Content

-

How to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

.jpg;maxWidth=300;quality=90)