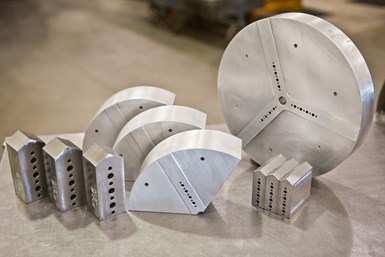

Dillon Pin Location Jaws Hold Sensitive Parts Without Deformation

Each jaw is CNC milled to provide maximum accuracy of workpiece location, enabling air chucks to hold sensitive workpieces firmly.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Takumi USA

Featured Content

View MoreDillon Manufacturing Inc.’s pin location jaws are designed to firmly yet safely grip deformation-prone parts. Well suited for thin-walled components, tubing-type products and other sensitive workpieces, Dillon manufactures full grip (pie) blank jaws and soft jaws for Northfield, Microcentric and others. Each is CNC milled to provide maximum accuracy for workpiece location, enabling air chucks to hold sensitive workpieces firmly. Standard sizes are available, as well as custom jaw sizes. Dillon pin location jaws are typically available in three days or less, according to the company.

Full grip jaws are manufactured for chuck sizes ranges between 4" and 10" diameters and are available in 1018 steel and 6061 aluminum. Jaw heights are available between 1" and 4". Soft jaws are available in 1018 steel and 6061 aluminum in heights from 0.75" to 5.00" and widths from 0.75" to 3.00".

Related Content

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

.jpg;maxWidth=300;quality=90)