Ceratizit Expands Range of Indexable Milling Tools

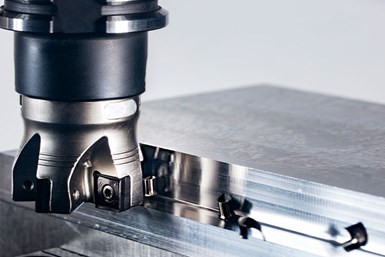

MaxiMill 491 features eight cutting edges per newly expanded 9-mm insert size, a precise 90° profile and a durable, nickel-coated tool body.

Share

Ceratizit introduces the new MaxiMill 491, adding to the company’s lineup of indexable milling tools. MaxiMill 491 features eight usable cutting edges per newly expanded 9-mm insert size, a precise 90° profile and a durable, nickel-coated tool body. According to Ceratizit, the MaxiMill 491 system is ideal for all shoulder and full-slot milling applications.

The MaxiMill 491 system enables users to quickly exchange inserts while the tool remains in the machine, reducing machine downtime while the precision-ground inserts deliver stable and smooth cutting due to Ceratizit’s Dragonskin coating technology. The Dragonskin coating gives the inserts added strength for demanding of machining conditions.

Configured with a positive insert geometry, the MaxiMill 491 is said to ensure excellent surface quality and dramatically increase tool life. The tool’s eight usable insert cutting edges also provide a low price per edge.

Ceratizit initially launched the MaxiMill 491 in a 12-mm size with a nominal diameter range from 32-160 mm and a corner radius of 0.8 mm. The company extended the range with the addition of 1.2-mm, 1.6-mm and 2.0-mm corner radii. The new 9-mm insert size now brings flexibility for more applications.

With this smaller size, more inserts can be mounted in the tools for longer tool life and higher chip removal rates. The new size also reduces power consumption, making the MaxiMill 491 effective for use with lower-power machine tools.

Related Content

-

Nidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

.jpg;maxWidth=300;quality=90)