Nidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

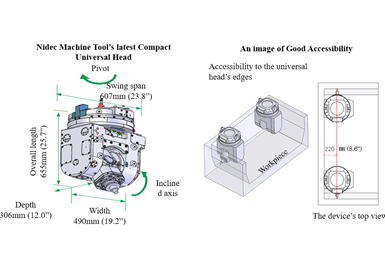

Nidec Machine Tool Corp. has launched a new universal head (UH), an attachment of the company’s MVR series of double column-type milling machines with five-face machining capability. The UH is said feature a more compact size than conventional products, while maintaining the spindle capability with high output and speed.

This small UH enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

This new UH has an inclined axis with an extended toolholding projection, enabling a better accessibility with a workpiece and the use of short and small tools. Additionally, even in machining processes that require long tools, this UH’s stiffer main spindle enables a variety of machining, from rough to finish machining. Also, with the UH able to approach up to 220 mm (8.6") to the wall, due to an improved swing span and interference range, the interference area with a workpiece has become smaller, and it can perform the precision machining on small and thin works and deep corners.

To secure better efficiency, this UH has a spindle speed of 20-6,000 rpm, a spindle motor output of 15 kW/420 rpm and a spindle maximum torque of 341 Nm, while providing faster indexing time of each axis, shorter machining time due to stiffer attachments and other features to improve productivity.

Additionally, the UH has a high degree of freedom in machining and is capable of handling a wide range of works, from cast heavy-duty cutting to high-precision, mold-finish machining.

This UH can be installed into the company’s double column-type milling machining with five-face machining capability, MVR·Ax and MVR·Hx.

Related Content

-

Kennametal's Expanded Tooling Portfolio Improves Performance

The company has launch eight new products that expand on and support existing platforms across multiple applications.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Ceratizit Expands Range of Indexable Milling Tools

MaxiMill 491 features eight cutting edges per newly expanded 9-mm insert size, a precise 90° profile and a durable, nickel-coated tool body.

.png;maxWidth=300;quality=90)