Renishaw Partners With Verisurf, Expands CMM Software

With an emphasis on Verisurf’s CMM Programming and Inspection Suite, this agreement gives companies access to Renishaw’s REVO five‑axis measuring system and the Equator flexible gauging system.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

Takumi USA

Featured Content

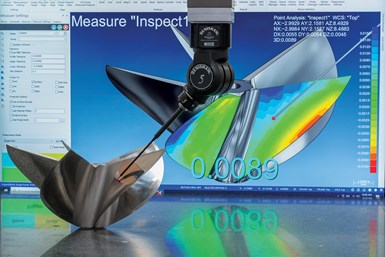

View MoreRenishaw has entered into an agreement with Verisurf Software Inc., enabling companies in North America to access Verisurf coordinate measuring machine (CMM) software from Renishaw. With an emphasis on Verisurf’s CMM Programming and Inspection Suite, this agreement gives companies access to Renishaw’s inspection technologies, including the REVO five‑axis measuring system and the Equator flexible gauging system, as well as the support networks of both organizations.

“We have been converting Renishaw Equator gauging systems into CMM Master shopfloor CMMs, and supporting the PH10 and SP25 solutions for years, so adding value to the PH20 and REVO five-axis systems was a natural progression. We recognize the continuing advancement of this technology and plan to support other REVO sensors,” says Ernie Husted, president and CEO of Verisurf Software Inc.

“At Renishaw, we appreciate the continued support of our product line by Verisurf. Fast and easy CMM programming, along with the five-axis Spiral, Edge and Pocket scan types, add to our customer promise of five-axis efficiency and overall performance,” says Denis Zayia, president of Renishaw USA.

Related Content

-

4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

-

Turning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

-

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)