Ballbar Testing Benefits Low-Volume Manufacturing

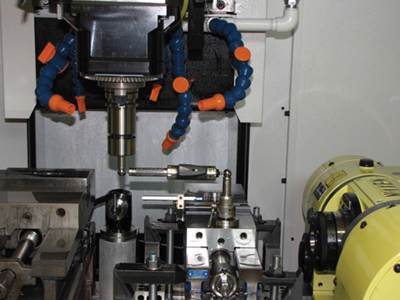

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Share

Renishaw’s QC20-W is a ballbar testing device that enables users to diagnose machine positioning errors. This can help users shorten lead times, reduce costs and improve repeatability.

Photos provided by Autodesk Inc.

All machine tools can benefit from ballbar testing to assess calibration. Machines can become misaligned for a variety of reasons, including environmental factors and wear and tear. Shops are often surprised to learn, through testing, that their machines are misaligned, as the Autodesk Technology Center in San Francisco recently discovered. After testing one of its five-axis machining centers with a Renishaw ballbar, the shop found the machine was unexpectedly out of alignment.

From Software to Hardware

Autodesk Inc. is known for developing design and manufacturing software, such as Fusion and Inventor, but the company also operates four Technology Centers across North America and Europe that enable the company to perform R&D, as well as test and validate software workflows. “We leverage our Technology Centers to study where the industry is going, have a practical environment for testing and developing our software, and demonstrate what's possible," says Mary Elizabeth Yarbrough, manager, Autodesk Technology Center in San Francisco.

The global Technology Centers have many overlapping capabilities, but each maintains a distinct focus. The San Francisco location has a strong advanced manufacturing focus with equipment, robotics and workspaces to support the exploration of new ideas around traditional manufacturing. The location's offerings include two five-axis machines, a hot-wire deposition hybrid machine, three-axis milling machines, waterjet and laser cutters, and an additive shop with a range of polymer 3D printing processes. Toronto is home to advanced prototyping and validation tools, which include wood and metal fabrication capabilities, a CNC shop, polymer and metal additive manufacturing, and cobots. Teams conduct forward-looking research in areas such as generative design, artificial intelligence and human-computer interaction. Boston explores ways to advance the Architecture, Engineering and Construction (AEC) industry, housing equipment for manufacturing composite parts as well as metal powder additive manufacturing. The Birmingham, United Kingdom, location works with customers across industries to help develop new manufacturing and fabrication techniques.

The equipment in the Technology Center is primarily used by a global network of innovation leaders known as the Autodesk Technology Centers Outsight Network. The Outsight Network is a global community of resident teams from industrial, academic, and entrepreneurial sectors who are passionate about accelerating and researching design and manufacturing processes. Once resident teams are trained on the equipment, they are free to use it to build prototypes while maintaining control of their IP. As such, these facilities operate similarly to high-mix, low-volume operations.

Renishaw recently conducted ballbar training at Autodesk’s San Francisco Technology Center, during which the teams found that a five-axis VMC was out of calibration. Autodesk then sent the ballbar to its Toronto Technology Center, where the Toronto team found a recently reassembled machine tool to be misaligned.

Calibration Revelations

Renishaw recently conducted a deep-dive presentation on calibration and metrology at the San Francisco location, with members of the three North American Technology Centers in attendance. This included calibration of the location’s machining centers using a QC20-W ballbar, where one of its higher-end, five-axis VMCs was found to be “pretty far out of calibration,” according to Yarbrough.

“It's got a really big casting and relatively small work volume with a fixed head that only moves in Z, and the table moves in X, Y, A and C. Everyone was convinced it was going to be the most accurate machine and it was not, by a lot,” says Orion Beach, research and design engineer, Autodesk Technology Center in San Francisco. “Testing discovered a .006" position error in the XY plane.”

The misalignment was likely tied to the Technology Center’s location on an industrial shipping pier in San Francisco’s Embarcadero. Not only is the facility over water, but all of its machines must be seismically anchored due to earthquake hazards. “What we have learned through trial and error is that the tension of the seismic anchors matters,” Yarbrough explains. “It can bend the machine, so when we are landing machines and we are working with technicians to seismically anchor them we have to make sure the machine is being considered holistically. What's going on at the bottom can affect the machine writ large.” The machines were calibrated when they landed at the facility and again when they were moved during an upgrade to the CNC shop in 2021, but they hadn’t been tested since that calibration.

In a shop that focuses on prototyping, it can be difficult to tell if a machine is miscalibrated. The tolerances aren’t usually super strict, and parts are mostly one-offs so repeatability isn’t an issue. According to Beach, the mentality is usually, “If you make one and it works, great.” Yarbrough adds, “It would be a different story if we were a production shop.”

Renishaw’s software walks users through setting up and running the 10-minute test, as well as analyzing the data and diagnosing the machine.

Low Volumes, High Rewards

Ballbar testing has numerous benefits for both high-volume manufacturers and low-volume shops such as the Technology Centers. For one, it’s faster than bringing out a technician. “Enabling us to quickly check our machines’ health and accuracy is what the ballbar is really good for because getting a technician to do that work takes a long time. You have to book them several months out, and then the work itself takes pretty much all day,” Beach says. He adds that ballbars’ swift inspection is especially beneficial in an earthquake-prone area such as San Francisco, saying, “Potentially if there was a good shake, we could use a ballbar to check if the machines were out of alignment or if they were still good without having to bring out the technician.” The ballbar test takes about 10 minutes, and Renishaw’s software guides users through the process of setting up the test, capturing data, analyzing it and diagnosing the machine. The software also provides a report of specific machine positioning errors.

A ballbar can also help reduce costs and shorten lead times by producing usable parts on the first attempt. This is particularly helpful for R&D shops. As Denis Vasilescu, an industrial metrologist at Renishaw points out, these facilities often don’t have a lot of room for error when it comes to execution because there are so many variables in the design process. “When the manufacturing lot is small but high-dollar value, you don’t want machine capability to be an unknown variable,” he notes. Beach echoes this sentiment. “It's really nice to know that the machine is calibrated,” he says. “It's not something that we're going to have to fight when trying to make a precise part.”

Autodesk plans to send the ballbar kit to the Boston Technology Center next. Then the three locations will share the ballbar and incorporate testing into their regular maintenance plans.

Moving Up

The ballbar was then sent to the Technology Center in Toronto, which also experiences location-related machine calibration challenges. This facility is located in the West Tower of Toronto’s MaRS Discovery District complex. “To bring manufacturing equipment into our workshop, we use a service elevator with limited size and weight capacity. A majority of our machine tools have been stripped down, lifted up separately and reassembled in the shops," explains Brian Jeong, senior research and design engineer, Technology Center in Toronto. “With that, we have to make sure that the machine is fully calibrated.”

This was the case for a new three-axis machining center that recently arrived. "Renishaw visited our Technology Center to assist in running a number of ballbar tests on our new machine tool that was stripped and reassembled,” Jeong says. “As predicted, the results showed backlash and squareness errors due to misalignments. We're currently working with the manufacturer and technicians to resolve these errors through calibrations." Jeong says this can be a regular occurrence. Being that this is an R&D facility, it cycles through machines faster than a job shop, so it has a continual need for ballbar testing. “With the fast advancements in manufacturing equipment, our machines are replaced more often than not to stay relevant to the industries that we serve,” he explains.

Lessons Learned

The next plan is to send the ballbar to the Technology Center in Boston. From there, the Technology Centers in North America plan to share the ballbar, sending it to whichever location needs it. They also plan to incorporate regular ballbar testing into quarterly and yearly maintenance plans.

Yarbrough says she and other Autodeskers have learned a valuable lesson from ballbar testing. “We made some assumptions about our equipment that were wrong, which was really a good thing to come to terms with,” she notes. “It helps us make sure there's accountability, because if this is a precision machine, it needs to be properly calibrated.” She adds that all the Technology Centers will benefit from this capability going forward. “It gives us peace of mind knowing if we need a super tight tolerance part, we could turn that out on any machine confidently.”

Related Content

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

Read MoreTurning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreRead Next

Raising the Bar with Ballbar Testing

Few manufacturing companies rely on ballbar testing to maintain machine tool accuracy as thoroughly as Silfex. Now, advanced training and a move to a Renishaw QC20-W wireless system have enabled the company to take the benefits of ballbar testing to a higher level.

Read MoreWireless Ballbar Speeds Medical Machine Testing

The QC20-W wireless ballbar from Renishaw enables this precision-machined medical device manufacturer to perform faster, more convenient CNC machine capability tests and produce a representative measurement of volumetric positioning accuracy.

Read MoreBallbar Basics—Running around in Circles

A ballbar testing system has three main components: the ballbar, a precision magnetic mount that attaches to the machine table, and a second precision magnetic mount that attaches to the machine spindle or spindle housing.

Read More