MTConnect in Context

The MTConnect interoperability standard is an enabling technology for the Internet of Things in manufacturing.

Share

The [MC]2 Conference is an annual event dedicated to MTConnect, the open-source interoperability standard for manufacturing equipment. The most recent edition of this conference (April 28-30) was a bit different than its three previous occurrences. The theme of this year’s conference was transforming a business with data-driven manufacturing and the industrial Internet of Things. Past conferences focused primarily on the development and implementation of the MTConnect standard, with many of the presentations centered on MTConnect-enabled applications for machine shops, such as machine monitoring. In contrast, this year’s conference covered the broader context in which this standard plays a vital role.

This new tone and perspective for the conference was evident in the opening day keynote address delivered by Bryce Barnes, Cisco’s senior manager of the machine and robot segment. In his introduction, Mr. Barnes cited this definition of the Internet of Things: It is the intelligent connectivity of smart devices by which objects can sense one another and communicate, thus changing how, where and by whom decisions about our physical world are made. He noted that MTConnect is an enabling technology for the Internet of Things in manufacturing.

Specifically, Mr. Barnes outlined the main principles that give the emerging industrial Internet of Things the power to “connect the unconnected” in the factory environment. He explained that this universal industrial network will be built around open software architecture, open protocols and open data models. Proprietary elements will not be allowed to create barriers for users or developers of applications operating in the Internet of Things. It will be layered, context-driven and identity-based. This structure will minimize risks to data that is transmitted, stored and analyzed, largely by cloud-based applications. It will provide pathways by which systems, data, software and protocols can grow and be renewed.

Mr. Barnes predicted that sensors will continue to proliferate on and in factory machines so that operators can take actions to keep production equipment running.

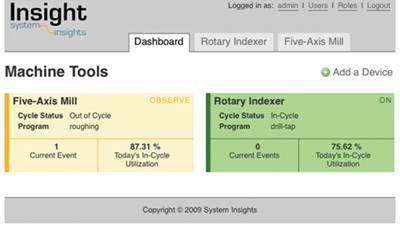

Following speakers at the conference picked up and amplified a number of these themes. For example, Athulan Vijayaraghavan, CTO of System Insights, Inc., noted that manufacturing has a particularly urgent need for intelligent conductivity. Manufacturing represents millions of devices, generating immense amounts of data—most of which “falls on the floor,” he said. Not being able to transform this data into information usable for decision-making is a huge loss—and a huge opportunity. MTConnect is helping meet the challenge of gathering, analyzing and presenting this data as developers tackle applications for real-time decision-making (at the process control level), “near-time” decision making (at the process improvement phase) and anytime/anywhere decision-making (at the management level). He stressed that keeping humans in the loop was both necessary and feasible because “people are sources of critical know-how. Developers must invite their feedback and involvement. Systems must provide transparency and knowledge sharing,” he said.

Other presentations offered examples of integrating data about cutting tools, high-speed metrology with laser scanning and robotic automation, and more effective decision-making. In this group of presenters, Chuck Matthews, a “cloud evangelist” with Machining Cloud GmbH, urged manufacturers to create a digital product strategy that represents “the journey you take your customers through and experience that you must optimize to be successful.”

Likely the most closely followed session of the conference was a panel discussion on industrial cybersecurity. Government and industry experts stressed that the threat to a manufacturing company’s data network was real, that attackers can operate from anywhere in the world, and that the danger of these attacks is growing. The good news is that advice and assistance for implementing effective (but not invulnerable) protective measures are more widely available than many companies realize. What is critical is that manufacturers recognize the threat and respond by availing themselves of these resources.

Workshops on the technical aspects of MTConnect development and implementation closed the conference on the afternoon of its third day.

Related Content

Machine Monitoring Boosts Aerospace Manufacturer's Utilization

Once it had a bird’s eye view of various data points across its shops, this aerospace manufacturer raised its utilization by 27% in nine months.

Read MoreShop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreRead Next

MTConnect Is For Real

Introduced at IMTS 2008, this communications protocol for CNC machines and other manufacturing equipment is already helping shops and plants implement effective machine monitoring systems. Although these "early adopters" are motivated by the long-term promise of enterprise-wide efficiency gains, their experience with pilot projects shows that benefits derived in the short term are substantial and worthwhile.

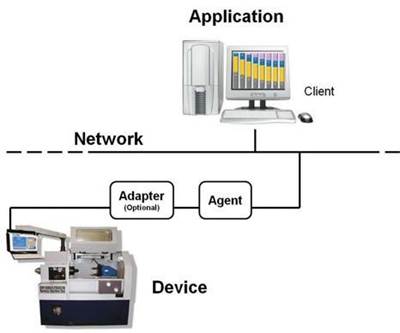

Read MoreUnderstanding MTConnect Agents and Adapters

MTConnect agents and their corresponding device adapters are simply small computer programs that work together so that MTConnect can make shop equipment and networks more readily connectible. In a nutshell, adapters enable existing shopfloor devices “to speak MTConnect,” and agents enable MTConnect messages and data files to be transmitted across a network to MTConnect-compatible applications.

Read MoreMT Connect: Two Shops Share Their Experience

For two shops in northern Indiana, using MTConnect for machine monitoring was just the start. Both shops are now ready to implement other promising applications.

Read More

.jpg;maxWidth=300;quality=90)