MMS Blog

The Value of a "Pathfinder Part" for Additive Manufacturing

Implementing additive manufacturing means starting somewhere. Seeking out the right pathfinder part can illustrate valuable lessons about the advantages of this technology.

Read MoreLook Again — Multiprocess Machine Tools Hint at Machine Shop Changes

The acceptance of complex machine tools has measurably increased. Recent articles offer a multifaceted look at multitasking machines.

Read MorePutting People First: a Profitable Strategy

Treating people fairly and valuing their contributions isn't only the right thing to do. It’s also a direct path toward greater profitability, as shown by this Top Shop.

Read MorePhoto Gallery: Top Shops Expo

Top Shops Expo took place this week in Cincinnati. The event featured exhibitors, speakers, a Made in the USA podcast panel and an award presentation for Top Shops honorees.

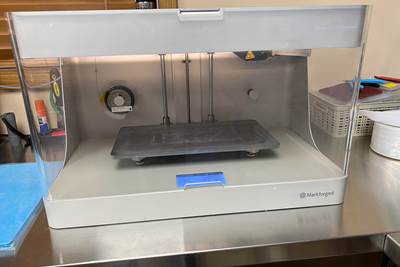

Read More3 Uses for a Composite Polymer 3D Printer in a CNC Machine Shop

When RPG purchased its metal 3D printer, a polymer printer was part of the deal. Three uses this job shop has found for this fused filament fabrication system.

Read MoreA More Efficient Way to Cut Near-Net Parts

Choosing the right milling insert is important: This insert from Iscar is designed for finishing near-net shaped parts quickly, while another makes high-feed machining more accessible with existing machining centers.

WatchTop Shops Are Data-Driven by Definition

CNC machine shops at various stages of digitalizing their operations share a commitment to evidence-backed decision-making.

Read MoreHow a Mom-and-Pop Becomes a Top Shop

Process and culture shift as leaders adopt new business strategies and a singular focus on expanding and filling capacity.

Read MoreExplore Additive Manufacturing with AM Radio

Additive manufacturing editors Stephanie Hendrixson, Peter Zelinski and Julia Hider talk industrial 3D printing on a new podcast.

Read MoreSimulation Saves Money When Machining Expensive Parts

Jobs machining expensive materials mean Keselowski Advanced Manufacturing needs to be extremely cautious. The operations manager says Vericut not only prevents mistakes, it shortens cycle times.

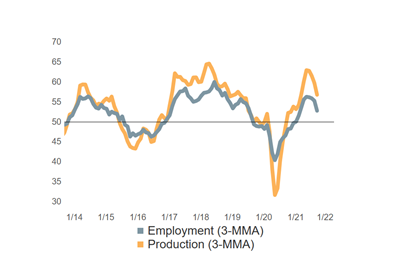

Read MoreMetalworking Production Impaired by Payrolls and Supply Chain

Stalling payrolls and congested supply chains weigh on production, as the metalworking index signals slowing expansion.

Read MoreMMS Is Back on the Shop Floor, But There Are Differences

Modern Machine Shop editors visit machining facilities to report stories. We are now more mindful than ever that the chance for this visit is a privilege. Meanwhile, what we are there to report has changed.

Read More