-

SPONSORED

-

-

-

-

-

MMS Blog

Coming: Stable Milling Speeds Determined In The Office

A utility available online may be the starting point toward software that can predict optimal spindle speeds outside the shop, without the user having to test or measure every tooling combination.

Read MoreMotor Type Vs. Machine Design

On a machining center, the choice of ballscrews or linear motors may not be as important as where the motors apply their force.

Read MoreChatter Control For The Rest Of Us

This shop finds stable milling speeds quickly using a systematic pattern of test cuts.

Read MoreTen Questions About Chatter

If you want to use a high speed milling spindle to machine aggressively, then information about chatter should be more than just background noise. Here are some basics.

Read MoreSelf-Improving CNC

This control feature lets a CNC running the same part several times get better and faster with each attempt.

Read MoreCarbide Prices Bring Attention To Replaceable Tips

Small-diameter milling and drilling tools with replaceable tips not only save on carbide cost, but also save on tool management and inventory costs.

Read MoreSelecting High Speed Tooling Requires A Balanced Approach

Plug in the right choices, use the right formulas and repeatability, reliability and improved productivity result.

Read MoreA New Face To Parts Chucking

Mechanical face drivers offer an alternative to other types of traditional chucking methods. Using mechanical face drivers for turning applications often provides increased flexibility and lower cycle times. Face drivers turn both very small and very large workpieces, and they also allow interrupted and heavy cuts. The major benefit of a face driver is that it allows the workpiece to be completely turned from one end to the other in one operation.

Read MoreGet Lean, Go Global

A successful manufacturing company must achieve world-class capability within its walls. At the same time, a company has to go after global business opportunities. Hanel Corporation (New Berlin, Wisconsin) is a case in point. It has implemented several U-shaped production cells that help the company keep costs down and productivity up. At the same time, company leaders have aggressively courted customers in countries around the world by offering both tangible and intangible values.

Read MoreWhen Disaster Strikes

If your equipment was damaged or destroyed by flood or fire, would you know what to do?

Read MoreMaking A Flexible Machine Tool More Flexible

Multitasking cutting tools can maximize the flexibility of multitasking machines.

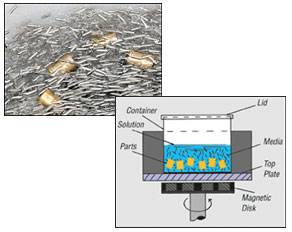

Read MoreDeburr Small Parts With Swarming Stainless Pins

This deburring system uses magnetism to excite small pins that remove light burrs from small, non-ferrous parts.

Read More