MMS Blog

Simple Organization

Some might say I'm obsessed with it, but even something as basic as labeling tools can boost your shop’s efficiency and ultimately add to its bottom line.

Read MoreMachines Grind Super Hard Materials

EMO 2017: Agathon will introduce a line of machines designed for super hard materials, including PCD.

Read MoreArcing away from Near-Net Forging

An electrical arc process joins a field of additive manufacturing technologies that could one day provide aerospace manufacturers with alternatives to near-net-shape forgings.

Read MoreMaking Tooling More Cost Effective

Something as simple as trading standard retention knobs for a longer version could help eliminate bulge in V-flange tooling and the problems associated with it.

Read MorePrecision Boring Head Enables Easy and Accurate Adjustment

Westec 2017: Allied Machine & Engineering will be highlighting the Wohlhaupter VarioBore precision boring head.

Read MoreCAD/CAM Software Gets Streamlined User Interface

Westec 2017: Autodesk will present the 2018 versions of its major CAD/CAM software including PowerMill.

Read More3D Printing Versus Additive Manufacturing: What’s the Difference?

Stories within the August issue of Additive Manufacturing magazine address this question.

Read MoreTechnology Corrects Spindles Working Independently

EMO 2017: Licon will present its i3 technology, which enables correction of spindles working independently of each other.

Read MoreSiemens Outlines Five Stages of Digitalization in EMO 2017 Preview

Siemens presented five stages of digitalization with end-to-end solutions from its integrated portfolio at a preview of its 2017 EMO exhibit.

Read MoreSimulation Software Reduces Debugging, Improves Cycle Times

Westec 2017: Spring Technologies will demonstrate its NCSIMUL Solutions simulation software, highlighting the NCSIMUL Machine and NCSIMUL 4CAM modules.

Read MoreAutomation Events Highlight Deburring

This tedious, costly and complex operation was one focus of two complementary, same-day events that covered virtually every aspect of industrial robotic automation.

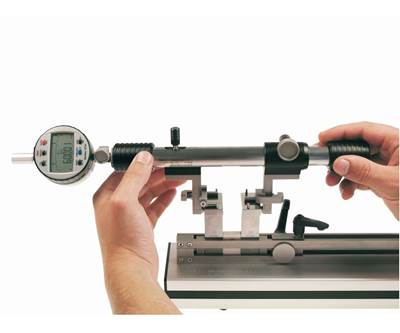

Read MoreWhat to Know About Adjustable Bore Gages

These comparative instruments must be set to the required nominal size, and there are a number of ways to do this.

Read More