MMS Blog

Changing Cutting Tools Solves Three Problems in Hard-Turning Application

By switching to a new boring bar, a contract shop that specializes in precision Swiss turning and machining reduced one part’s cycle time by more than seven minutes.

Read MoreBuying an HMC: Peripheral Equipment Considerations

Is it time to move up to an HMC? Let’s consider some of the peripheral equipment that HMC buyers should think about.

Read MoreDoor Isolates Hazardous Operations While Enabling Access to Them

Fabtech 2017: Dynatect’s Gortite VF automated machine safety door is designed to isolate hazardous operations from other industrial processes, material, equipment and people, while still enabling access to them.

Read MoreHow Dry Grinding Permits Coolant-Free Gear Making

Grinding the external forms of automotive gears came to be the last step still needing coolant. This machine eliminates cutting fluid by combining gear grinding with dry skiving in the same cycle.

Read MoreVision System Assists On-Machine Probing for Fast Setups

The camera on this VMC combined with a tablet-like control helps speed and simplify on-machine probing routines during new job setups.

WatchAre AM Parts as Strong?

The technology’s use for replacement of a flight-critical part says they are.

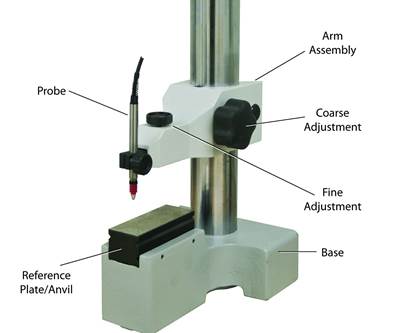

Read MoreHow to Choose the Right Bench Comparator Stand

Understanding a comparator gage’s features and characteristics will help you choose the right one for your application.

Read MoreHow to Effectively Run a Company

Answering fundamental questions can help you figure out how effectively your company is running.

Read MoreMaintaining Productivity with Repeat Business

Recurring tasks need to be streamlined and sometimes performed offline.

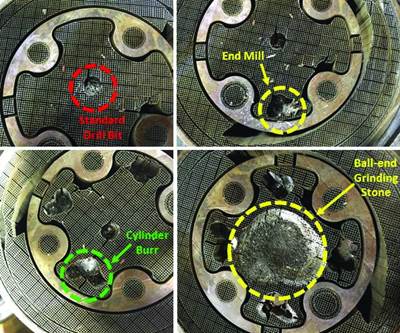

Read MoreRemoving Metal Supports from Additively Manufactured Parts

What is the best way to remove metal support structures from AM parts?

Read MoreBlast Room Enclosures Available in Flexible Sizes

Fabtech 2017: Clemco will feature its PDQ predesigned blast room enclosures.

Read MoreOpen Machine Opens Options for Large Pipe, Plate

These verticals leverage open workzones, mobile spindles and creative workholding to minimize downtime in 3D machining of large parts or multiple small parts.

Read More