Open Machine Opens Options for Large Pipe, Plate

These verticals leverage open workzones, mobile spindles and creative workholding to minimize downtime in 3D machining of large parts or multiple small parts.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View More

Large-part machining doesn’t have to be overly complicated. This is the thinking behind the Flexdrill CNC, a machine designed to reduce downtime on unwieldy tube, plate, pipe and sheet workpieces that often require multiple setups on one or more machines that are too small to accommodate the entire part.

Developed by the makers of Flexarm tapping units, the Flexdrill CNC’s most obvious difference from other machine configurations is its open design. With no enclosure, there’s no physical impediment to loading and unloading parts. The spindle, unencumbered by a fixed mount, travels the entire length of this open bed, a distance that can be as long as 80 feet, depending on user needs. Along with an automatic toolchanger, this configuration enables the machine to perform milling, drilling, tapping, beveling and form-drilling anywhere in the workzone without manual intervention—capability that also makes it useful for multiple, small parts.

Other downtime-reducing features include:

Fourth-Axis Fixturing

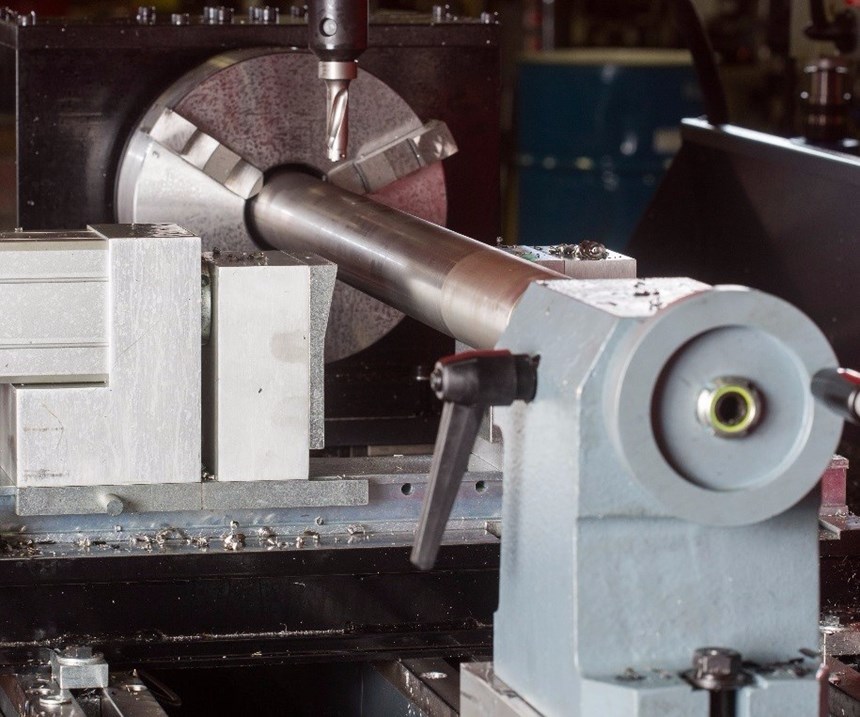

Even when material removal is limited and tolerances are forgiving, 3D geometry can add significant time and cost to machining large parts. That’s particularly true for lengthy tube and pipe components that require multiple setups and even manual indexing because they don’t fit properly in standard CNC machines. On the Flexdrill CNC, fourth-axis rotary fixtures, including both chuck/steady-rest combos and rotary tables that travel linearly along the Y axis, facilitate 360-degree, single-setup access to a wide variety of parts.

Pendulum Mode

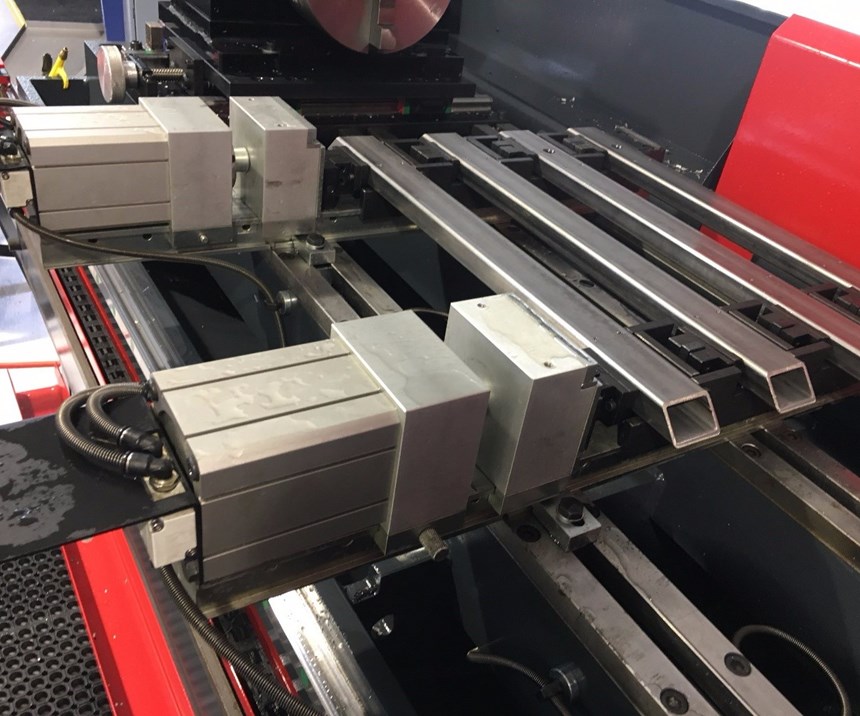

Rotary fixtures, vises, clamps and other workholding components all mount to parallel T-slot rails stretching the length of the bed. In addition to facilitating end-to-end access to the largest workpieces, this configuration enables setting up multiple, smaller parts in different areas of the workzone for sequential machining in a single, uninterrupted cycle. What’s more, operators can perform these setups while the spindle turns by running the machine in pendulum mode, which dissects the workzone into distinct cells divided by light curtains. The spindle won’t cross these light curtains, and if the operator does, the machine shuts down.

Universal, Multi-Part Vises

Featuring quick-release pins, these systems enable operators to adjust the clamping range to anywhere between 0.5 and 23 inches by simply flipping a switch. Vise inserts designed specifically for this system enable users to divide that clamping range into as many as four individual clamping stations. Installing these inserts takes less than 90 seconds. Round-material vises are also available.

Accessories and Customization

The Flexdrill CNC is designed to be customized to the user’s needs. To that end, workholding options include custom and turnkey systems as well as the standard selection of fixtures. As for the machines themselves, other accessories include through-spindle coolant, programmable lubrication, Renishaw probes that help define work coordinates, and mobile control panels.

Customization starts with one of two platforms: the TRD, and the GRD, a gantry-type machine. The TRD ranges from 10 to 80 feet long with a 16-inch Z-axis travel. It offers a CT- or BT-40 spindle with maximum continuous torque of 184 foot-pounds. The GRD ranges to 80 feet long with a 19.5-inch Z-axis travel and a Y axis ranging to 10 feet wide. It offers a CT-50 spindle option and a maximum continuous torque of 368 foot-pounds. Both models feature a color touchscreen control with ISO G- and M-code programming, 40 GB of storage, and USB/ethernet program loading, as well as mono-block, welded-steel frames and T-slot beds.

Read Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=150)