Understanding Absolute and Incremental Compensation

Learning to manipulate absolute and incremental CNC compensation can not only extend the life of a given machine but also ultimately result in improved manufacturing flexibility, accuracy, and quality.

Share

Introduction

In today’s manufacturing environment, it is more and more commonplace to utilize laser measurement systems for the calibration of CNC machines. After all, companies routinely calibrate the gages they use for verifying dimensional information so why not go ahead and do the same for the equipment that create the dimensions? The benefits of a preventive maintenance program that includes the calibration of CNC machines are many. Reduced scrap, reduced rework at the detail and assembly level, and increased shop floor flexibility are just a few. Add to this the ability to know if a machine is adequate to manufacture a given part before putting it on the machine (or getting the work) and it all adds up to give you significant insight into the manufacturing capabilities of an organization.

However, there is a problem with the process. Today’s shops have a myriad of machines with many different types of controls that have different capabilities, communication methods, and varying approaches to compensation. These variables combined with today’s leaner and meaner maintenance organizations present quite a challenge to those who need to utilize the electronic compensation inherent in the controls. Maintenance groups across the country (and world) struggle with the issue of compensation.

Not too long ago, I was working for a rather well known laser manufacturer and had the unique opportunity to travel all throughout North America talking to end users of the equipment. By and large, the most common question was, well the laser is great, but, "How do you comp this machine?" The more I traveled, the more I heard the same question. I even had conversations with machine tool control manufacturers of many varieties and explained to them that the great compensation they were making available in their controls was fantastic but that unfortunately, nobody knew how to take advantage of it – it just wasn’t clear.

In this article, we will seek to get some foundational theory underneath the various types of compensation and further attempt to give examples of its formulation. For simplicity sake, we will focus on linear compensation. Future articles will begin to deal with aspects of straightness and squareness compensation. Ultimately, we will touch on the aspects of volumetric compensation. However, first things first: let’s start with linear.

Background

Before we dive in, please let me say that it is not my intent to endorse any specific type of compensation in this series of article or further more any brand of control. As will become clear in future articles (and most of you likely already know this), they all have their strengths.

There are two basic types of compensation available in today’s controls: Absolute and Incremental. Incremental compensation is typically found in Japanese controls and Absolute compensation is found in most others. As the details of these types of compensation are investigated, it may be seen that there are advantages in each of the approaches.

Absolute Compensation

With absolute compensation, individual points stand alone. For the most part, the value entered into the control is the opposite value of the error observed, however, this depends on the control. Consider the error profile depicted below where the first column represents the measured point and the second column the measured error. This is typical of the linear data obtained from a laser measurement system:

Point Error

1 0.002

2 0.004

3 0.002

4 0.001

5 0.001

6 -0.001

7 -0.002

8 -0.003

9 -0.002

10 0

The resulting compensation for an absolute control is then:

Point Error Compensation

1 0.002 -0.002

2 0.004 -0.004

3 0.002 -0.002

4 0.001 -0.001

5 0.001 -0.001

6 -0.001 0.001

7 -0.002 0.002

8 -0.003 0.003

9 -0.002 0.002

10 0 0

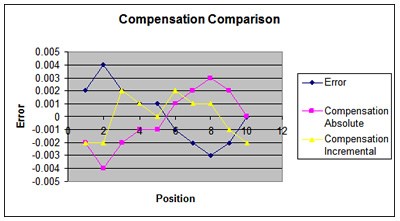

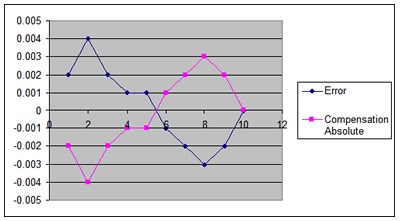

Based on the absolute model, it should then be expected that the graphs of the error versus the compensation to show an inversion from one another as shown below:

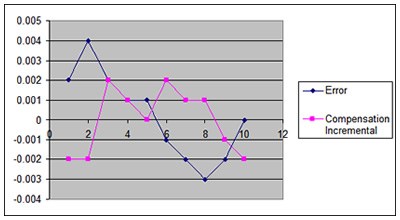

Incremental Compensation

Basically, incremental compensation operates under the premise that each point influences the other. That is to say, changes in a previous point (from a given point) will influence all points from there on to the end of the string. While initially this may seem somewhat cumbersome, it can be quite useful. In situations where some relatively modest scaling may be seen, the modification of the first compensation value will be felt through the entire curve.

When working with incremental compensation, the values are additive from one point to another. Going back to the same error profile mentioned in the discussion of the absolute compensation model, the differences may be seen. Again, the first column represents the point number with the second column representing the associated error as measured by a laser.

Point Error

1 0.002

2 0.004

3 0.002

4 0.001

5 0.001

6 -0.001

7 -0.002

8 -0.003

9 -0.002

10 0

The first point would be -.002 (to get to zero), the second, another -.002, the third, .002 and so on. Note here that the compensation value is the change from one point to another as opposed to the absolute value as explained earlier in the absolute compensation discussion. The final compensation table would then look like:

Point Error Compensation

1 0.002 -0.002

2 0.004 -0.002

3 0.002 0.002

4 0.001 0.001

5 0.001 0

6 -0.001 0.002

7 -0.002 0.001

8 -0.003 0.001

9 -0.002 -0.001

10 0 -0.002

To compare the two methods simultaneously, please see the graph shown below. This shows the overall error, the absolute compensation, and the incremental compensation graphs overlaid.

Exercises

A sample set of exercises has been included (along with answers) with this article so that this may be practiced.

Summary

Certainly it is said by many users of controls, laser, and associated software that the absolute compensation method makes more intuitive sense. As mentioned before, this type of compensation is seen on mostly non-Japanese controls however the reality is that, once understood, both compensation approaches offer unique abilities. Either way, with today’s shops, one is bound to find both types of controls. Learning to manipulate both types of compensation can not only extend the life of a given machine but also ultimately result in improved manufacturing flexibility, accuracy, and quality.

Sample Exercises

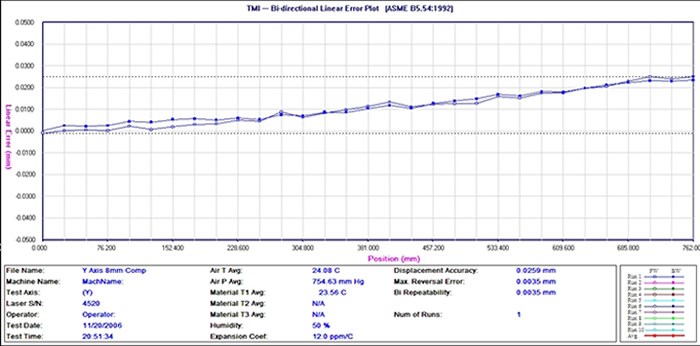

The graph below formulates compensation values based upon both incremental and absolute controls. Note the dimensional data is given in millimeters.

The Raw Data:

Position Forward Error

0 -0.000991

25.4 0.000103

50.8 0.000484

76.2 0.000151

101.6 0.002265

127 0.00063

152.4 0.001902

177.8 0.002967

203.2 0.003343

228.6 0.00499

254 0.004481

279.4 0.008745

304.8 0.00625

330.2 0.008284

355.6 0.00981

381 0.011361

406.4 0.013371

431.8 0.011046

457.2 0.012257

482.6 0.012499

508 0.012693

533.4 0.015842

558.8 0.015212

584.2 0.017441

609.6 0.017538

635 0.019621

660.4 0.020493

685.8 0.022915

711.2 0.024853

736.6 0.023836

762 0.02495

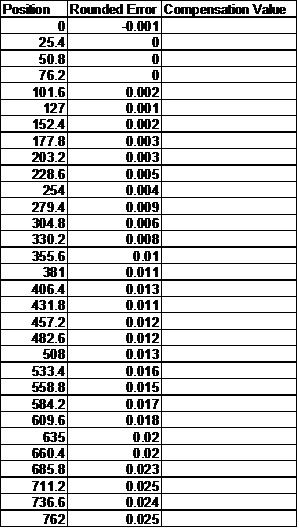

To begin your exercise, fill in the compensation values. For convenience, values have been rounded to the nearest micron. First, assume an incremental compensation approach.

The answers may be seen below:

Position Rounded Error Compensation Value

0 -0.001 0.001

25.4 0 -0.001

50.8 0 0

76.2 0 0

101.6 0.002 -0.002

127 0.001 0.001

152.4 0.002 -0.001

177.8 0.003 -0.001

203.2 0.003 0

228.6 0.005 -0.002

254 0.004 0.001

279.4 0.009 -0.005

304.8 0.006 0.003

330.2 0.008 -0.002

355.6 0.01 -0.002

381 0.011 -0.001

406.4 0.013 -0.002

431.8 0.011 0.002

457.2 0.012 -0.001

482.6 0.012 0

508 0.013 -0.001

533.4 0.016 -0.003

558.8 0.015 0.001

584.2 0.017 -0.002

609.6 0.018 -0.001

635 0.02 -0.002

660.4 0.02 0

685.8 0.023 -0.003

711.2 0.025 -0.002

736.6 0.024 0.001

762 0.025 -0.001

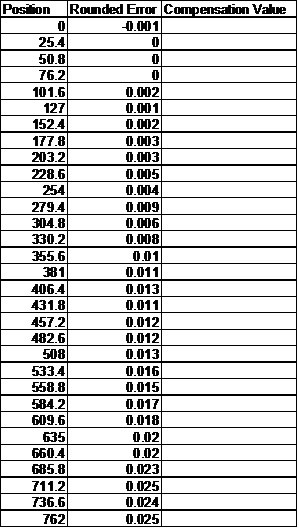

Next, look at the same data in absolute terms. Fill in your data in the following chart:

In absolute terms, the compensation then looks as follows:

Position Rounded Error Compensation Value

0 -0.001 0.001

25.4 0 0

50.8 0 0

76.2 0 0

101.6 0.002 -0.002

127 0.001 -0.001

152.4 0.002 -0.002

177.8 0.003 -0.003

203.2 0.003 -0.003

228.6 0.005 -0.005

254 0.004 -0.004

279.4 0.009 -0.009

304.8 0.006 -0.006

330.2 0.008 -0.008

355.6 0.01 -0.01

381 0.011 -0.011

406.4 0.013 -0.013

431.8 0.011 -0.011

457.2 0.012 -0.012

482.6 0.012 -0.012

508 0.013 -0.013

533.4 0.016 -0.016

558.8 0.015 -0.015

584.2 0.017 -0.017

609.6 0.018 -0.018

635 0.02 -0.02

660.4 0.02 -0.02

685.8 0.023 -0.023

711.2 0.025 -0.025

736.6 0.024 -0.024

762 0.025 -0.025

Related Content

How to Mitigate Risk in Your Manufacturing Process or Design

Use a Failure Mode and Effect Analysis (FMEA) form as a proactive way to evaluate a manufacturing process or design.

Read MoreWhat are Harmonics in Milling?

Milling-force harmonics always exist. Understanding the source of milling harmonics and their relationship to vibration can help improve parameter selection.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

Laser Calibration Insures Machine Tool And CMM Accuracy

Because it makes large precision-machined components for the aerospace, defense, medical, scientific, electronic, marine and petroleum industries, which require tight tolerances, laser calibration is a competitive advantage for this manufacturer.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)