Roughly seven years ago, Vivek Sarin stood at a crossroads. Shutting his U.S. plant and moving operations to China would likely ensure continued profitability, yet he was reluctant to abandon the community, country and core customers that had provided the foundation for his business’ success.

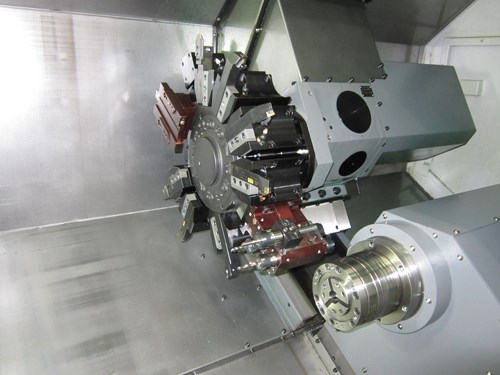

Looking back, the president and CEO of Shelby Industries says he is confident that he made the right decision. During the past half decade, the Shelbyville, Kentucky-based operation has kept its doors open and maintained profitability by diversifying its manufacturing capabilities, Mr. Sarin says. The latest example is the acquisition of a Samsung SL25ASY turn-mill from Dynamic International (Pewaukee, Wisconsin), an investment that marked the company’s first foray into advanced CNC machining. Since installation, the machine has not only helped the company become more self-sufficient in manufacturing its core product line, but also helped facilitate its expansion into new markets.

New Competition

Those two goals—bringing more core work in-house and diversifying the customer base—have formed the backbone of the company’s strategy since the mid-2000s, Mr. Sarin says. For Shelby Industries, that time period marked the beginning of what has become a familiar story to many manufacturers. What he calls a “perfect storm” of Chinese economic liberalization, U.S. policy decisions and other factors had led to the commoditization of the company’s principal business: trailer couplers, mechanical winches, trailer jacks and other towing and trailering components. Suddenly, Chinese manufacturers could produce virtually the same products for the U.S. market at 25 to 30 percent less than Shelby’s material costs. “It was becoming clear that our business was facing a competitive threat the likes of which we had never seen,” Mr. Sarin says.

Starting in 2008, the company began to reposition itself. During the next few years, it would move to provide contract manufacturing, custom fabricating, material-handling products, precision machining and logistics services. Nonetheless, Mr. Sarin still saw a place for the work that had made up the majority of the company’s business for nearly 25 years at that point.

Building on Self-Sufficiency

Shelby-brand towing and trailer components trace their roots to the early ‘80s, when Mr. Sarin’s father purchased the business. Having emigrated from India with nothing but “a suitcase and the opportunity for an education,” his father instituted a culture of self-sufficiency at the company that persists to this day, Mr. Sarin says. Shelby has always taken full responsibility for designing and marketing its product line as well as much of the manufacturing.

However, reducing part costs enough to be competitive would require bringing even more capability in-house. Although Shelby’s 110,000 square feet of manufacturing space had long been home to equipment for various fabricating, coating and assembly processes, the company was still reliant on outside suppliers for much of its machining work. Mostly, this involved the large number of variations of shaft-type parts used in the production of its core product line. In fact, the company had been outsourcing as much as 80 percent or more of these shafts, estimates Randall Soudom, director of business development—tooling and fabrication. “Some of these shafts are quite complicated, and they require milling capability in addition to turning,” he says. “We wanted to find a way to manufacture such parts at our own facility without a lot of secondary operations.”

Mr. Soudom approached Meredith Machinery, a trusted local supplier in nearby Louisville. Together, he and Meredith sales representative Ken Hoefflin began researching various machine models and conducting test cuts. Eventually, the two settled on the Samsung SL25ASY. Along with the machine, the company purchased a Master 865 bar feeder from Iemca (Charlotte, North Carolina) and a parts catcher to enable lights-out operation.

Flexible, Done-in-One Production

The SL25ASY turning center features a Y-axis turret with ±2 inches of travel for off-center milling, drilling and tapping capability. The machine’s subspindle, driven by a 10-hp motor, features full C-axis indexing capability. These features enable the company to produce virtually all of the various iterations of its shaft-type parts in a single setup, Mr. Soudom says.

One factor that set the Samsung machine apart from others the company considered was rigidity, Mr. Soudom says. According to the manufacturer, the machine’s cast iron structure provides damping and thermal displacement, while a single-tube-type, 30-degree slant-bed design ensures minimum bending and torsion during heavy-duty cuts and high speed turning operations. Mr. Soudom adds that mounting both the turret and subspindle on box ways, as opposed to linear guides, also contributes to rigidity.

Another major benefit of the bar-fed turn-mill is that change-over times are minimal, Mr. Soudom says. That’s partially because of the nature of the shop’s shaft-type parts, the majority of which are machined from 3/4-inch-diameter barstock. As such, operators spend very little time swapping bar diameters in the feeder, and when they do, those change-overs take mere minutes, Mr. Soudom says. This also enables lengthy lights-out runs.

Still, change-overs wouldn’t be nearly as fast if it weren’t for the flexibility provided by the machine’s tool turret and gang-tool slide, says Bill Crabtree, director of business development—precision machining. In fact, between the 24-position turret (12 positions for work on the main spindle, 12 for the subspindle) and the three-position slide, the machine is equipped to process more than 30 different components at a moment’s notice without the operator having to change or touch-off tools. The company has fitted some positions with the same tools to avoid interrupting production if one breaks, especially during lights-out runs. In that case, the machine will automatically detect the breakage and select a redundant tool. The turret is also quick to change to the next tool, Mr. Crabtree notes. With non-stop, bi-directional indexing, the turret takes 0.2 second to move to the next position.

The company also appreciated the fact that the machine was available with collets for both spindles in addition to standard, three-jaw chucks. Manufactured by Hainbuch (Mequon, Wisconsin), the collets offer quick-change capability that contributes to faster change-overs when needed, Mr. Crabtree says. More importantly, the collets proved more repeatable than the three-jaw chucks. Using a collet also enables machining much closer to the spindle nose.

Other factors also contributed to the company’s decision to purchase this particular model. For one, the subspindle can sync its rotation with the main spindle to avoid stopping during part transfers. In addition to saving time, this reduces wear and tear on the machine, Mr. Soudom notes. The machine also runs more quietly than other models he considered. Finally, as with any equipment purchase, one of the most important considerations was the ability of the local supplier to meet the company’s needs. “This machine was available almost immediately and at 2/3 the cost of another model we considered, which would’ve taken six months to ship,” he recalls. “Also, Meredith Machinery will send guys out for service or training within an hour of getting the call.”

Supporting Diversity

Since installing the SL25ASY, Shelby Industries has brought 45 percent of previously outsourced shaft work in-house, Mr. Sarin says. However, the company’s vision for the turn-mill went beyond reducing production costs for its towing and trailer components. “By investing in precision machining technology, we are not just vertically integrating to support our core product line. We are also enhancing our marketability to new industries,” he explains.

One of the biggest industries in the area is automotive, and Shelby was quick to market its new machining capability to the two local Ford plants and their numerous Tier 1 and Tier 2 suppliers in the region. It has also taken on a number of jobs for the military, such as hardware for antennas and safety railing for naval vessels. The company also plans to pursue opportunities in the medical industry, Mr. Crabtree says.

The new machine has supported Shelby’s diversification in more indirect ways as well. New business, especially from the company’s new custom fabrication shop, has led to a greater need for jigs, fixtures, stamping dies and the like.

While the company has always maintained a small selection of toolroom mills, lathes and surface grinders, much of this work has historically been outsourced. With the SL25ASY, the company can cost-effectively produce all these components in-house. Additionally, it has begun to provide such tooling for other local manufacturers, Mr. Sarin says.

In the future, Shelby Industries is likely to make further investments in precision machining capability, marking a “whole new venture for our team,” Mr. Sarin concludes. “We look forward to becoming more self-sufficient and attracting even more business, and we’re fortunate to have the space and the financial means to make it happen.”

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)