TIMTOS Takeaway: Smart Manufacturing Is Automated

Data-driven manufacturing was the stated theme, but Taiwan’s largest metalworking exhibition was also an excellent showcase for the automated equipment that this technology supports.

Share

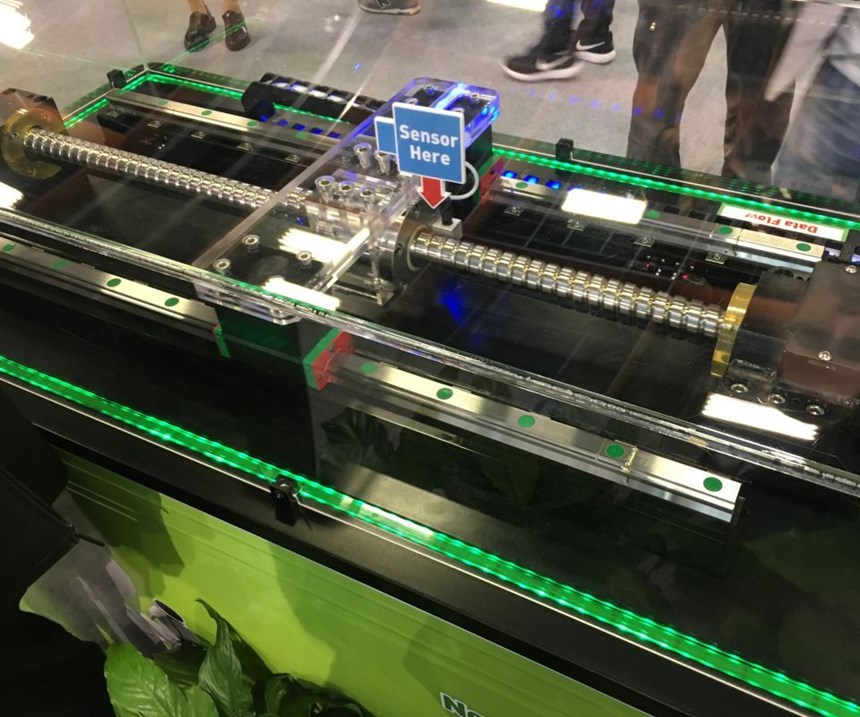

There wasn’t much time to examine the intricate orchid blossoms lining the halls of the show floor before a blaring speaker called the diverse pack of reporters to attention. Italy, Germany, Turkey, Brazil, South Korea, Mexico—all these countries and more were represented among the eager faces of the international trade press, waiting with notepads and cameras ready for the week’s first formal appointment. All had been invited to Taiwan’s largest metalworking trade show largely to see technology innovations like the one touted by the man with the microphone: a networked cell with machines automatically adjusting parameters based on real-time sensor feedback.

Highlighted by the Far East Machinery Company (FEMCO), this cell was just one of many displays focused on data-driven manufacturing among the 5,340 booths comprising TIMTOS 2017. It also ranked among the most ambitious. Tellingly, however, even the more modest “smart” manufacturing exhibits assumed a certain level of technological capability among the show’s 55,000 attendees, the purported users of this technology. In short, simpler, commodity machines seemed rare, and automation was everywhere. Although there's promise in data-driven manufacturing for virtually any manufacturer (if only on the level of basic machine monitoring), these exhibits suggested its full potential may well be reserved for highly automated, technologically sophisticated operations.

Yet, TIMTOS also demonstrated the extent to which data-driven manufacturing is really all about supporting automation. After all, the end game is essentially the same as installing a robot or pallet changer: to trust tasks—in this case, data mining, analysis, and even decision-making—to technology rather than human beings. All in all, the Taiwanese suppliers provided an excellent showcase for the kinds of technology and processes increasingly required to not only become a true part of what has been touted as the Fourth Industrial Revolution, but to compete in the modern era in the first place.

Bursting at the Seams

Hosted March 7-12 in Taipei, the island nation’s biggest city and home to a third of its roughly 24 million people, the 26th edition of TIMTOS was bigger than ever despite a modest global machine tool sales slowdown in 2016. Exhibitor and attendee counts both set records for the biennial show, and traffic was robust by any measure, with throngs in seemingly every booth exchanging business cards (two-handed with a slight bow, as is customary in Asia) and filing carefully around the aforementioned floral arrangements (gifts to exhibitors from happy customers and other business relations).

Still, there was plenty of space to move around, largely because the show was so spaced out. Attending TIMTOS means taking (thankfully short) bus rides among three different locations in Taipei. Show organizers TAMI, the Tiawan Association of Machinery Industry, and TAITRA, the Taiwan External Trade Development Council, acknowledged in a press conference that this situation is unfortunate. However, representatives added that the problem will soon be remedied by the pending completion of an entirely new hall, adjacent to the main one, that will keep all exhibitors in the same area. The new hall will also help accommodate more booths for exhibitors that are reportedly eager but currently unable to participate in Asia’s second largest and the world’s fifth largest manufacturing technology trade show.

Betting Big on Big Data—and the Underlying Tech

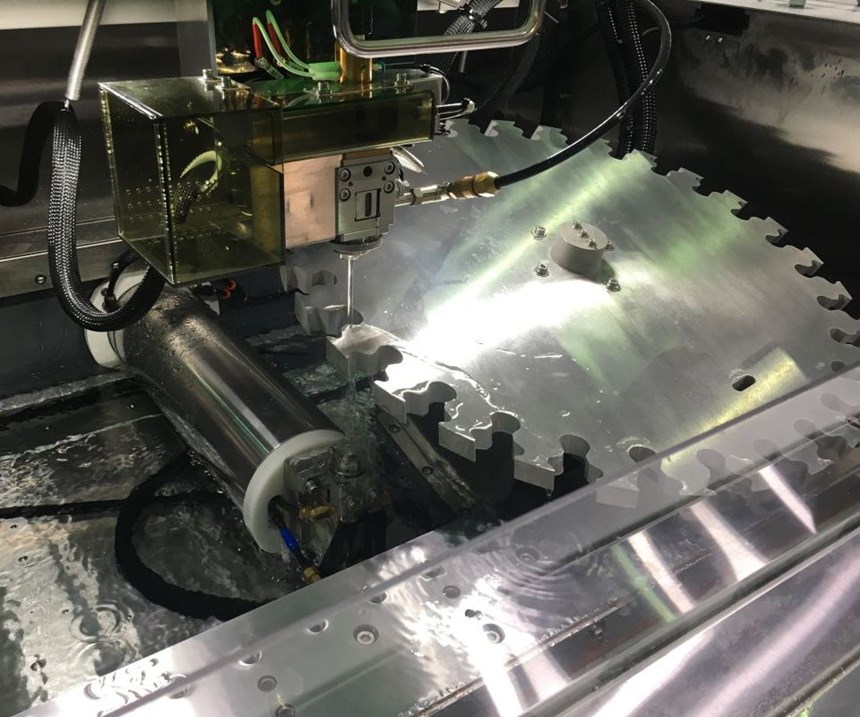

In addition to worldwide market trends, the Taiwanese embrace of “smart” manufacturing is being driven by the government. Another priority for further innovation is national defense, and judging from the prevalence of aerospace-focused technology on the show floor, machine tool builders are responding to a government push for domestic production of military aircraft. Show organizers made clear that both areas are top priorities in the continued development of Taiwanese machining technology.

Government aside, organizers claimed that Taiwan’s strong information and communications technology (ICT) industry, responsible for much of the country’s rapid growth during the past four-odd decades, provides a natural edge in developing and implementing data-driven technology. They also noted that Taiwan is rich (and known for cost-competitiveness) not just in machine tools, but also in the components and secondary systems upon which those machine tools rely. (TIMTOS was also rich in these offerings, with one of the three show halls largely dominated by these exhibitors.) Close integration between the two industry segments was cited by show organizers as a competitive edge in effectively developing and implementing data-driven manufacturing technology.

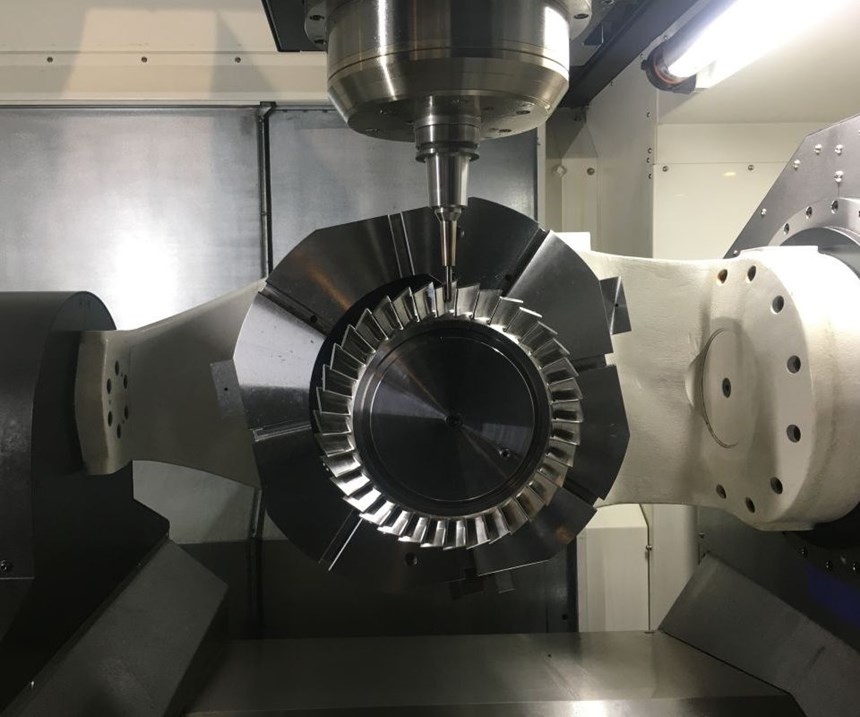

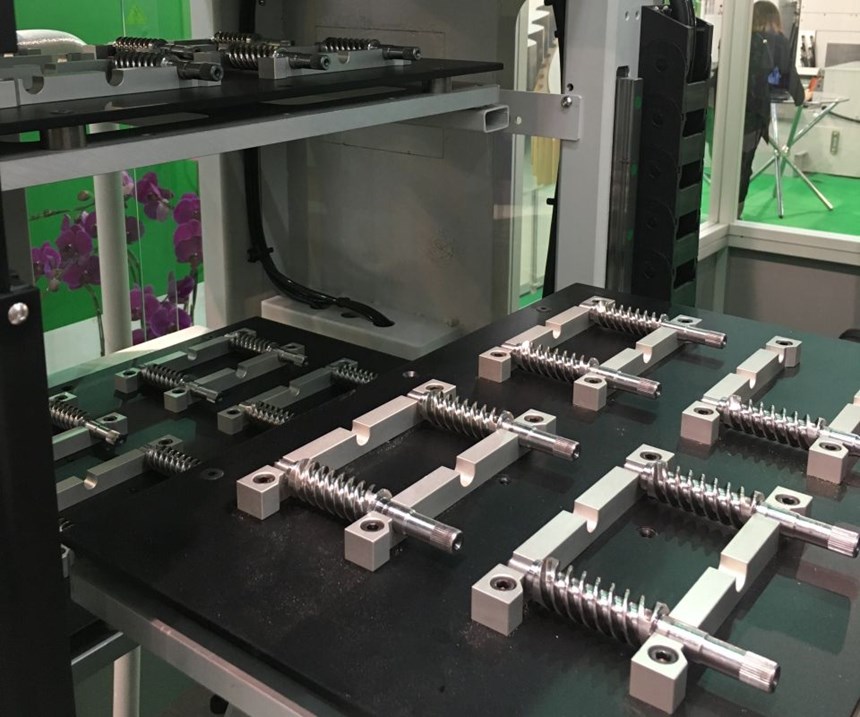

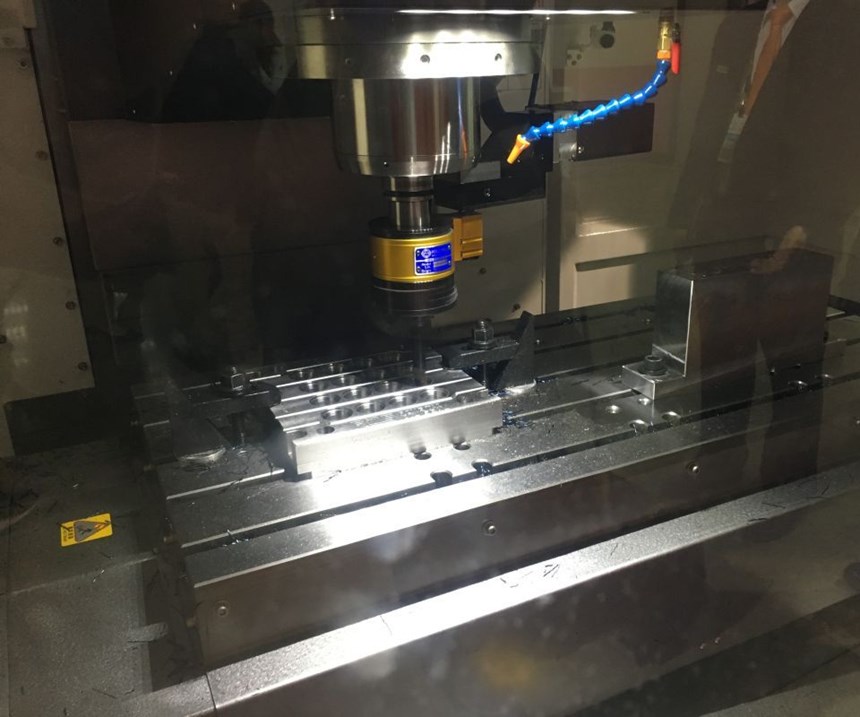

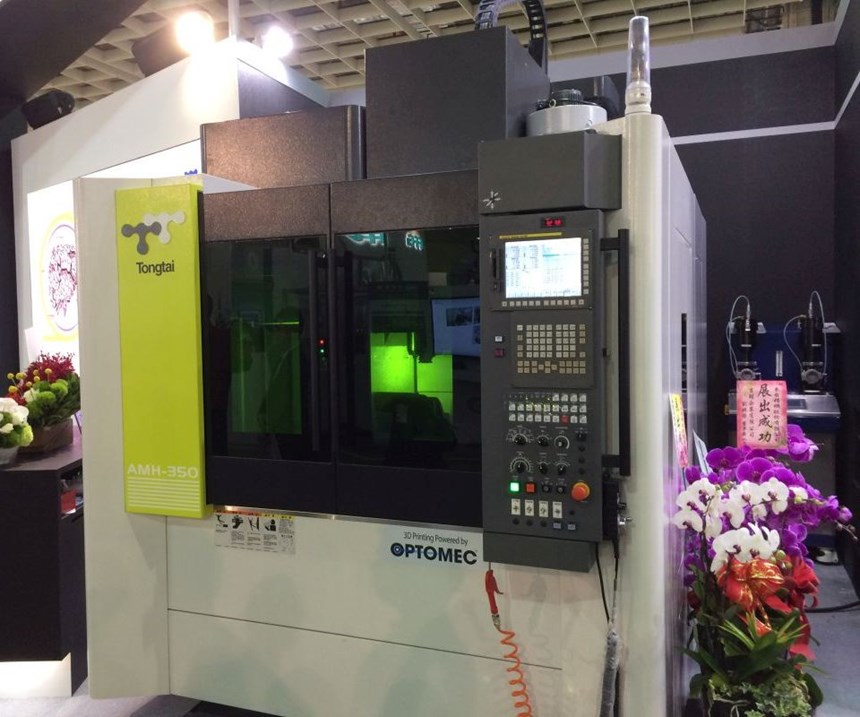

A tight-knit supply chain exchanging information and resources has long benefitted the domestic industry’s global competitiveness in a more general sense as well. And, the machines incorporating these components are becoming ever more advanced. Although many offer general-purpose machines, most exhibitors seemed more eager to tout technology developed for specific applications and industries. For example, multiple machines on display offer both high-torque and high-speed operation to satisfy aerospace demands. Linear motors were a relatively common option for motion, and many CNCs featured touchscreens with customized HMIs. Multi-axis and/or multitasking machinery was the highlight of most builders’ booths. Perhaps most notably, it was rare to find a machine not tethered to a robot, pallet changer or other form of part-handling automation. Suffice it to say, TIMTOS exhibitors aim to compete on more than just price.

Following this path makes sense for Taiwan. After all, a “factory of the future”—one that relies on technology to obtain and perhaps even act independently on data—is automated by definition. It’s hard to imagine that automation being limited to only the data-driven side, and it’s equally hard to imagine such operations running competitively without the kinds of technology described above.

There may be a new Industrial Revolution underway, but plenty of manufacturers aren't quite ready to start setting up cloud-based networks of interconnected machinery. For them, shows like TIMTOS can demonstrate not only what's possible, but also the technology and processes that can help prepare an operation for getting there. Scroll through the picture gallery above for notable examples of both.

Related Content

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreManufacturer, Integrator, Software Developer: Wolfram Manufacturing is a Triple Threat

Wolfram Manufacturing showcased its new facility, which houses its machine shop along with space for its work as a provider of its own machine monitoring software and as an integrator for Caron Engineering.

Read MoreProtecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More