The Indispensable Toolroom

By steadily improving its equipment and processes, a toolroom becomes the fountainhead of a worldwide manufacturing operation.

Share

Toolrooms play crucial roles in supporting the daily production of many machine shops. But while a shop's main production area may be bright, clean and equipped with the latest CNC machinery, the toolroom typically houses older, manual equipment in an atmosphere that suggests metalworking's primitive roots.

Because they serve primarily in backup roles, toolrooms can become almost invisible features in many shops. For this reason, the toolroom's inherent capabilities are usually taken for granted. These capabilities include substantial versatility that derives chiefly from the increasingly rare talents of skilled, conventional machinists. But when the parent "shop" is a worldwide manufacturing business with more than $1 billion in annual revenues, the role of a singular toolroom becomes both conspicuous and remarkable.

The Power Of Ideas

Sensormatic Electronics Corporation (Boca Raton, Florida) is the world's largest manufacturer of electronic security solutions for the protection of merchandise and personnel. The company manufactures a large variety of products for article protection, video surveillance, access control and asset tracking.

Customers include 93 of the world's top 100 retailers, and the firm is the Official Electronic Security Supplier and a sponsor of the 2002 Winter Olympic Games in Salt Lake City, Utah. Sensormatic currently employs more than 5,700 people worldwide and sells products in 113 countries. The company has manufacturing facilities in Puerto Rico, Ireland, Brazil and China.

Sensormatic was originally established in 1966 on the strength of a simple idea. At that time, founder Ron Assaf was working in a supermarket when he noticed a shoplifter carrying a bottle of wine out the door. After unsuccessfully pursuing the thief, Mr. Assaf decided to devise a method to reduce or eliminate shoplifting losses.

During the ensuing three decades, the demand for article protection devices exploded, and Sensormatic became a world leader in this industry. Last year alone, the company sold more than 3.85 billion Ultra-Max security tags—the firm's most widely used product. These electronic, anti-theft tags can be fastened in concealed locations to all types of merchandise—from CD cases to flashlight battery packages.

The company's toolroom operation developed in response to its constantly changing product line—driven by customers' continuous introduction of new consumer products, packaging and merchandising methods. During fiscal year 2000, for example, the company introduced more than 30 new products for electronic article surveillance. As recently as the early 1990s, however, Sensormatic still depended on outside suppliers to meet its substantial tooling needs. At the same time, not having in-house capability to design, fabricate and maintain the firm's highly-specialized production machinery presented challenges.

Given these realities, the company took advantage of another simple but powerful idea. The idea was to create a central toolroom at the company's Boca Raton headquarters that would build all the machinery and tooling for its entire global operations. In 1993, Sensormatic hired Tony D'Angelo, a seasoned tool-and-die machinist and process engineer, to organize and manage its Global Innovation Machining Division.

With 25 years of experience in the aerospace industry, Mr. D'Angelo initially assumed that the company's machining needs would be comparatively simple. But this impression soon changed as Mr. D'Angelo began to address the firm's wide-ranging tooling needs.

"Sensormatic's shop initially consisted of only three or four people with a few outdated, manual machines. The facility was used primarily as a fit-up shop for maintenance and assembly of equipment," says Mr. D'Angelo. "After much analysis, we convinced upper management that it was more economical to bring this work in-house, and the operation we have today saves the company a considerable amount of money."

Under Mr. D'Angelo, Sensormatic's new approach has been to manage the toolroom department as though it's an independent shop. From a corporate perspective, however, Mr. D'Angelo and his team are firm believers in the importance of serving internal customers. "My department is like a business within a business," he says. "We view the other departments in this company as our customers, because our shop exists to serve their needs."

Agility Plus Precision

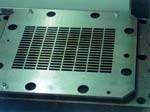

While creating an internal toolroom might not be feasible for many mass-production manufacturers, this strategy is well suited to support Sensormatic's rapidly evolving product portfolio. The majority of the firm's products incorporate various plastics manufactured by injection molding and vacuum forming. Therefore, a significant portion of the toolroom's work involves meeting the constant demand for new molds to supply the company's worldwide production facilities (Figures 1 and 2).

But Mr. D'Angelo's primary responsibility is helping to maintain company-wide production levels. The toolroom accomplishes this by creating and repairing parts for the firm's assembly-line machines and delivering these items when they are needed. "If a part is needed to repair an existing machine on the production line, that request always receives our first priority," Mr. D'Angelo says. These custom-designed production machines fabricate millions of small, precisely dimensioned, plastic tags that are the mainstay products for the company.

Another important priority for the toolroom is to build production machines (Figure 3). While items required to maintain or ramp-up production always take precedence, the shop's normal workflow is dictated chiefly by part due dates, material availability and overall resources. But, according to Mr. D'Angelo, "normal workflow" can be difficult to define in a shop geared for flexibility in responding to immediate needs.

Typical of machine shops that produce multi-cavity molds for plastic parts, Sensormatic's toolroom must maintain precision tolerances while working with some extremely hard metals. Although many of its products are small and apparently simple, Mr. D'Angelo cautions that even tiny variations in tooling or machine parts can have serious ramifications. Because Sensormatic's customers attach these tags to their products with high speed, automated equipment, mass production operations can be disrupted by even small variations in size or shape. The electronic tags' performance characteristics may also be adversely affected by slight manufacturing variations.

Equipped For Efficiency

The personnel and equipment selected for Sensormatic's toolroom reflect its extraordinary role in the company's operations. Although this shop can shift gears quickly to produce a wide variety of parts and molds, much of its machinery compares favorably to that found in a high-production machine shop.

Sensormatic also places great emphasis on attracting highly skilled people. Including Mr. D'Angelo's 40 years of experience in the metalworking trade, the toolroom's 35 current employees have a total of more than 600 years of experience. The toolroom operates continuously 24 hours per day, 7 days per week, producing an average of 4,000 parts per month. Although he emphasizes that skilled people are difficult to find, Mr. D'Angelo says Sensormatic's toolroom offers talented people certain advantages that they would not enjoy if they worked for smaller, independent shops. He credits this factor for the company's success in attracting skilled machinists.

In addition to the human contributions, Mr. D'Angelo is a firm proponent of enhancing productivity by automating key processes. To date, the company has invested more than $2 million in its toolroom equipment. Regarding the return on this investment, Mr. D'Angelo says "Within 1 year after the installation of our first CNC cylindrical grinder, we had realized a savings of $2 million."

The shop's equipment inventory includes six Atlas two-axis knee mills; two Mitsubishi CNC cylindrical grinders; three Okamoto fully-automatic surface grinders; three four-axis CNC machining centers (two Mitsubishi and one Monarch); three variable-speed engine lathes with DROs; two Mitsubishi WEDM machines; and one Hansvedt MV-20 ram-EDM machine. At press time, the shop also was adding a new Mitsubishi ram-EDM machine and an Okada electrode mill.

The agility required in a toolroom that supports worldwide manufacturing operations depends on equipment that minimizes setup time and overall operator intervention. For this reason, the shop workhorses are the Atlas two-axis knee mills that incorporate MILLPWR CNC controls manufactured by Acu-Rite Inc. (Jamestown, New York). Clausing Industrial Inc. (Kalamazoo, Michigan) offers these CNC controls as factory-installed options on many of its Atlas machines.

The CNC unit functions as both a DRO and a fully-programmable control. Because it utilizes a menu-prompted, conversational format, no previous programming experience is required to operate the control. As a program is created, the 10-inch, color LCD screen displays a graphic representation of each step in the machining process (Figure 4). The control also includes a built-in calculator to solve geometry and trigonometry problems, and math results can be imported directly into the part program. Design data from a CAD file may also be imported into the control, and multiple part programs may be stored in the control's memory or saved via its internal 3.5-inch disk drive.

The control unit also simplifies some key machining tasks. For example, the control's "skew" feature enables the operator to set up a workpiece without aligning it perfectly in reference to the worktable's X and Y axes. The control automatically compensates for the particular angle offset throughout the machining cycle. If a machinist is creating a part by the conventional, manual method, the control's "teach" function simultaneously copies and saves this procedure as a CNC part program. The control also incorporates a Position-Trac feature that utilizes software to quickly reset the workpiece zero following a power interruption.

Because the CNC control can operate a milling machine with substantially less operator oversight or intervention, labor efficiency increases dramatically. "With the CNC controls, we've found that we gain an extra one-half person per machine," says Mr. D'Angelo. "This equates to gaining one additional toolmaker at no additional labor cost for every two machines that we operate."

Although the shop's EDM section has existed for only two years, it's already well-equipped. In addition to the Hansvedt sinker machine, EDM specialist Bob McIlwain operates two Mitsubishi FX20K wire-EDM machines. These machines accept 44-pound wire spools that permit a maximum of 80 hours unattended burn time. Both Mr. D'Angelo and Mr. McIlwain emphasize that the need for excellent finish smoothness is crucial to their mold production. Mr. D'Angelo expects that the shop's new Mitsubishi EX-22 ram-EDM machine with a 16-position automatic tool changer will speed up his current EDM process by a minimum of 50 percent.

The effectiveness of applying advanced technology in a toolroom is well illustrated by the case of a special part that Sensormatic uses for many of its production machines. This part is a slitter/roller that incorporates multiple, evenly-spaced blades composed of D2 tool steel that is heat treated to 65Rc (Figure 5). These slitter/rollers cut sheets of styrene into narrow strips that are used to manufacture the firm's security tags. Because dulling of the slitter blades is a constant occurrence during mass production runs, the company needs a continuous stock of sharp replacements to maintain its operations. Before the shop invested in CNC cylindrical grinders that can sharpen one of these parts in approximately 2 hours, approximately 50 hours of manual sharpening was necessary per part.

Measurement is another time-consuming job for machine operators. This can involve measuring tool offsets for machine setups or verifying the quality of in-process or finished parts. Sensormatic's toolroom subjects parts to a rigorous procedure that includes first-off, in-process and final inspections. For the majority of its inspection work, the shop uses a Bright Apex CMM manufactured by Mitutoyo and equipped with a CNC probe manufactured by Renishaw (Schaumburg, Illinois). For measuring smaller, lighter parts, the shop uses an Avant Zip Video Measuring System from Optical Gaging Products, Inc. that incorporates a stationary probe and a moving stage.

Although the amount of time required to measure offsets for a single tool by conventional means might be relatively small, the cumulative time spent to measure every tool used during an entire workday can be substantial. To save time and improve production, Mr. D'Angelo recently ordered a Kelch Vega-E automatic tool presetter.

When machine shops upgrade equipment, the toolroom might be the last place considered for new investments. Demonstrating the great potential of a toolroom driven by the latest technology, however, Sensormatic's Global Innovation Machining Division strongly suggests that conventional assumptions are changing. The application of new technology is certainly no less potent in the toolroom than it is in the machine shop at large. Besides playing a supporting role for larger-scale metalworking operations, the modern toolroom also has the capability to step up to the plate in a close game and hit a home run.

Related Content

Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)